The Difference Between Virgin and Recycled Polyester: Environmental Impact Explained

Polyester dominates modern textiles because it’s strong, versatile, and cost-effective, but not all polyester is created equal. This guide breaks down how virgin polyester (PET) compares with recycled polyester (rPET) across production, environmental impact, cost, and performance so sourcing teams can make clear, defensible decisions.

When you’re ready to sample or scale responsibly, GNC Exports is a reliable, audit-friendly partner for virgin and recycled polyester fabrics across apparel, uniforms, bags, and industrial uses.

Quick definitions

- Virgin polyester (PET): Polymer made from petrochemical feedstocks (ethylene glycol + terephthalic acid), then extruded into fiber.

- Recycled polyester (rPET): Same polymer, but made from existing PET waste, primarily post-consumer bottles (and increasingly textiles) via mechanical or chemical recycling.

How they’re made (and why it matters)

Virgin polyester (PET)

- Raw materials: Non-renewable petroleum derivatives.

- Polymerization: Energy-intensive condensation under heat/catalyst to create PET.

- Fiber formation: PET chips are melted, extruded, drawn, and spun into yarn; then woven/knit into fabric.

Implication: High dependence on fossil inputs and process energy.

Recycled polyester (rPET)

Two routes:

- Mechanical recycling (dominant today): Bottles are sorted, washed, flaked, re-melted, and spun. It can slightly shorten polymer chains over cycles.

- Chemical recycling (emerging): Depolymerizes PET back to monomers (e.g., BHET/DMT) and re-polymerizes into “virgin-equivalent” PET quality parity, but currently costlier and less scaled.

Implication: Avoids new oil extraction and a chunk of the primary polymerization energy.

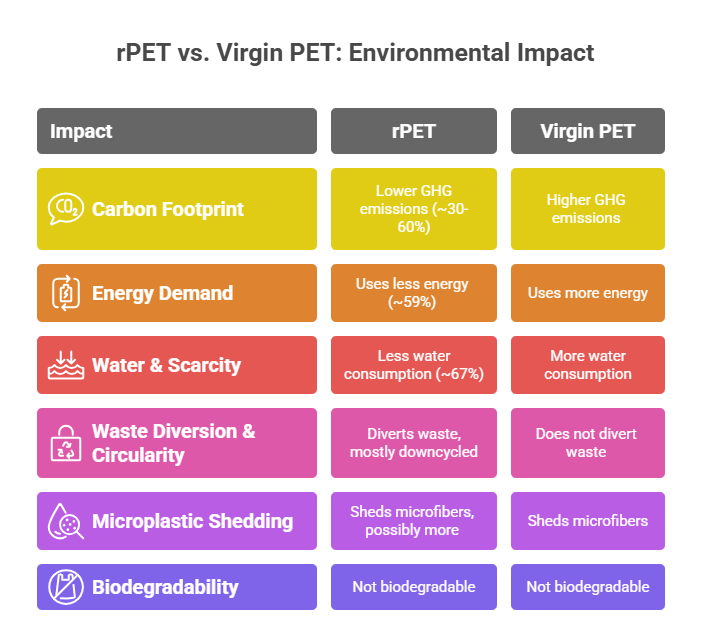

Environmental impact: where rPET clearly wins (and where both need work)

- Carbon footprint: rPET typically cuts GHG emissions ~30–60% vs. virgin PET; one LCA shows ~42% lower GHGs for recycled yarn.

- Energy demand: rPET can use up to ~59% less energy than virgin production material when multiplied over large volumes.

- Water & scarcity: Recycling uses less water; studies report ~67% lower freshwater consumption and significantly lower water-scarcity impacts for rPET.

- Waste diversion & circularity: rPET diverts PET waste from landfills/oceans (bottle-to-fiber is mainstream today). Caveat: much current rPET is downcycled (bottles → textiles) and not yet re-recycled at end of garment life until textile-to-textile systems scale.

- Microplastic shedding: Both shed microfibers during use/wash. Some tests show recycled knits can shed more (shorter) fibers, so filtration and design choices matter.

- Biodegradability: Neither is meaningfully biodegradable; end-of-life planning is essential.

Bottom line: rPET is materially better on carbon, energy, water, and waste diversion, but microfiber management and true circularity require parallel action (design, laundry filtration, take-back, and chemical/enzymatic recycling scale-up).

Cost & supply reality

- Virgin PET still benefits from mature, massive scale and tends to be cheaper.

- rPET typically carries a 30–70% premium depending on region and grade, driven by feedstock competition (bottle-to-bottle vs. textiles), collection/sorting costs, and limited high-quality supply. Long-term contracts, blended programs, and regulatory tailwinds can help stabilize.

What can buyers do now?

- Lock multi-year rPET supply where possible.

- Use blends (e.g., 30–70% rPET) to balance budget and impact.

- Prioritize certifications (e.g., GRS/RCS) for traceability and claims integrity.

Engage suppliers (like GNC Exports) who can manage dye/quality controls at the batch level.

Performance & quality: near-parity with a few watch-outs

- Strength/durability: rPET is very close to virgin; mechanically recycled fibers may be ~5–15% weaker in some constructions, often mitigated via fiber engineering or modest virgin blending. Chemical recycling achieves parity.

- Handfeel & comfort: Comparable rPET fabrics can be equally soft (sometimes softer). Moisture-wicking and quick-dry characteristics are the same polymer chemistry, so construction drives performance.

- Dyeing/whites: rPET base can skew off-white/yellowish depending on feedstock; achieving optical whites/light pastels may need extra steps and tighter QC. Final colorfastness and vibrancy are excellent with the right process controls.

Side-by-side summary

Aspect | Virgin Polyester (PET) | Recycled Polyester (rPET) |

Feedstock | New petrochemicals | Post-consumer PET (mainly bottles), growing textile-to-textile |

Carbon & Energy | Higher energy & GHGs | 30–60% lower GHGs, up to ~59% less energy |

Water | Higher freshwater use (process) | Lower freshwater use (~67% less) |

Waste | Adds new plastic to the system | Diverts waste, but today it is often downcycled |

Microfibers | Sheds | Also sheds (sometimes more/shorter); filtration helps |

Biodegradability | Not biodegradable | Not biodegradable |

Cost (’25) | Lower | Premium vs. virgin |

Strength | High | Near-parity; minor loss in some cases (mechanical) |

Dyeing | Whites/pastels are easier | Extra steps/QC for optical whites |

Best use today | Cost-sensitive basics | ESG-aligned lines, outdoor/sports, uniforms with targets |

Choosing the right option for your line

- Corporate/ESG-led programs: Prioritize high rPET content (or 100% rPET where feasible), backed by GRS certification and supplier traceability.

- Uniforms & workwear: rPET works well for twills, oxford weaves, and blends where durability and colorfastness are critical; validate tensile/abrasion specs and wash-to-shed performance.

- Outdoor & performance: rPET knits/wovens deliver equivalent wick/dry with recycled credentials; pair with design choices that reduce shedding.

Procurement checklist (save this)

- Specify content & scope: % rPET, mechanical vs. chemical route acceptable.

- Demand proof: GRS/RCS transaction certificates and batch-level traceability.

- Color management: Agree on tolerances for whites/pastels; approve lab dips early.

- Performance QA: Tensile, abrasion, pilling, colorfastness, and dimensional stability.

- Shedding controls: Fabric construction choices + laundry filter guidance.

End-of-life plan: Take-back pilots or partners to prepare for textile-to-textile loops.

Why source from GNC Exports

- Virgin & recycled capabilities: From commodity PET to GRS-certified rPET programs across apparel, uniforms, bags, and industrial fabrics.

- Tight QC on dyeing & handfeel: Proven processes to manage rPET base-tone variability and deliver consistent color across lots.

- ESG-ready documentation: Supplier declarations, test reports, and recycled-content certificates for your audits and product passports.

- Scalable contracts: Help lock supply and pricing via multi-season agreements.

Explore fabrics and request rPET swatches at GNC Exports → https://gncexports.in

Takeaway

If you’re reducing Scope 3 and aligning with circularity policy, rPET is the pragmatic step up from virgin PET with measurable cuts in carbon, energy, and water. Pair it with microfiber mitigation, tight color/QC controls, and credible certification and partner with GNC Exports to scale responsibly, on spec, and on time.

FAQs

Is recycled polyester as durable as virgin?

Generally yes for most end uses; mechanical rPET can be slightly weaker, but construction and blending close the gap. Chemical rPET achieves parity.

Does rPET really reduce emissions?

Yes expect ~30–60% GHG reduction per kg fiber, with one leading LCA showing ~42% lower GHGs vs. virgin yarn.

What about microplastics?

Both shed. Choose constructions that minimize shedding and encourage customers to use washing filters; consider design/laundry guidance on care labels.

Why is rPET more expensive?

Collection/sorting/reprocessing plus feedstock competition (bottle-to-bottle) keep rPET at a premium for now; long-term contracts and scaling help.

Can rPET be recycled again?

Yes, but mechanical loops shorten chains over time. Expanding textile-to-textile chemical/enzymatic routes is key to true circularity.

Contact Information

- Mon - Sat: 10:00am-7:00pm

- 4/32-33 Triveni Nagar , Meerpur Cantt , Kanpur-208004

- +91 9839708040 | +91 9936159591

- gncfabrics@gmail.com

Quick Links

- About Us

- Products

- Blog

- Contact Us

© 2024 GNC EXPORTS, All rights reserved. Developed by DIGI PEXEL

- Privacy Policy

- Terms & Conditions

- Cookies Policy