Recycled Polyester Twill Fabric vs Standard Polyester Twill: Strength, Durability, and Cost

Choosing between recycled polyester twill (often written as rPET twill) and standard/virgin polyester twill is no longer a simple “eco vs. performance” decision.

Modern recycled yarn systems have closed most of the performance gap, leaving procurement teams weighing small differences in mechanical strength and abrasion against a modest cost premium and a sustainability upside.

This guide breaks down the strength, durability, and cost trade-offs with practical sourcing advice and test specs you can use when writing RFQs.

What is polyester twill, and why compare recycled vs. standard?

Twill is a weave characterized by a visible diagonal rib that boosts drape, reduces wrinkles, and improves abrasion resistance versus plain weaves at similar weights.

Polyester twill (both virgin and recycled) is widely used across workwear and uniforms, fashion and athleisure, bags and outdoor gear, and upholstery because it is dimensionally stable, colorfast, quick-drying, and easy-care.

The recycled vs. standard distinction refers to the feedstock: rPET is made from post-consumer or post-industrial PET (e.g., bottles, waste yarns), while virgin uses newly polymerized PET chips.

In use, both are polyester; the polymer backbone is the same, so differences mainly arise from chain length distribution, spin quality, and finishing.

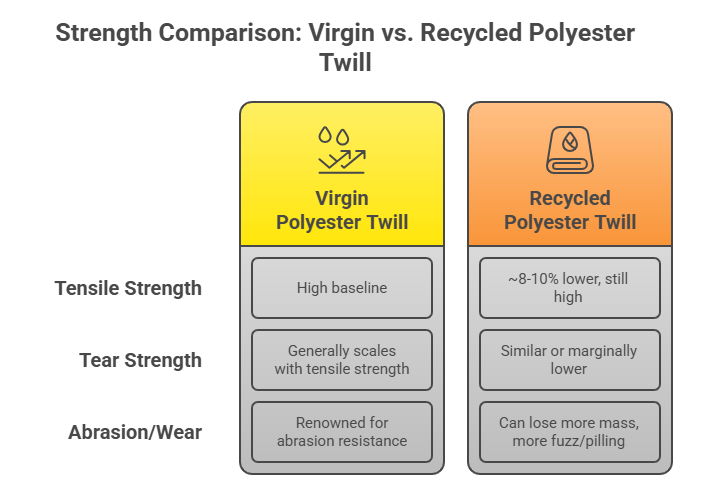

Strength: how do they compare under load?

Tensile strength (breaking force)

Virgin polyester twill sets a high baseline for tensile strength. Recycled polyester twill typically measures ~8–10% lower in tensile strength compared to like-for-like virgin constructions, still firmly in the “high” category for most apparel, bag, and uniform applications.

In aging studies, recycled polyester fabrics sometimes retained strength better than virgin under UV/heat exposure (smaller percentage drop), indicating comparable baseline strength with slightly different aging profiles.

What this means in practice: For garments, soft goods, and many upholstery specs, well-made rPET twill will clear common tensile requirements; for maximum-load, thin-margin designs (e.g., structural pack panels), virgin may offer a small safety cushion.

Tear strength

Direct twill tear data is limited, but tear strength generally scales with tensile strength. Expect rPET twill to be similar or marginally lower than virgin if other variables (denier, weave density, finish) are controlled.

Material choice in yarn type (filament vs. spun), weave density, and finishes will move the needle more than “recycled vs. virgin” alone.

Abrasion/wear

Polyester twill is renowned for abrasion resistance, but accelerated wear tests show recycled fabrics can lose more mass under rubbing than virgin equivalents, reflecting slightly higher fiber shedding under severe abrasion.

Expect surface fuzz/pilling to appear a bit sooner on rPET in high-friction zones. The gap can be narrowed with anti-pilling finishes, tighter constructions, and higher-tenacity filament selections.

Durability: performance over time and in the real world

Colorfastness and fading

Both virgin and recycled polyester twill are highly colorfast: they dye well and resist UV fading and washdown. In normal apparel or upholstery service, you should see minimal visible fade from either.

Pilling and surface wear

Polyester generally pills less than many blends, but rPET twill may show slightly earlier surface wear under heavy friction.

Finishing choices (enzyme/anti-pilling), higher filament counts, and tighter twills significantly mitigate this.

For uniform knees, elbows, pack bottoms, or seat cushions, consider upping GSM or adding reinforcement panels regardless of fiber source.

Environmental aging (UV/heat)

Polyester is naturally UV-stable relative to natural fibers. Under accelerated UV/heat aging, recycled fabrics have, in some studies, shown smaller strength loss percentages than virgin, suggesting comparable long-term stability.

In outdoor deployments, coating systems (PU, TPE, lamination) and UV-stabilized finishes influence lifespan at least as much as the polymer’s origin.

Bottom line on durability

For most apparel, gear, and upholstery applications, high-quality rPET twill lasts nearly as long as virgin twill; construction and finishing usually dictate lifespan more than “recycled vs. virgin.”

Cost: fiber, fabric, and the sustainability premium

Fiber pricing

Globally, recycled polyester fibers typically carry a ~15–30% premium over virgin due to collection/sorting, reprocessing, and certification steps. Indicative 2025 ranges cited in trade analyses: virgin ~US$0.85–1.05/kg, mechanical rPET ~US$1.10–1.40/kg (regional spreads apply).

Fabric pricing

At the fabric level (e.g., ~160 GSM twill), a baseline virgin polyester price around US$0.90/m in certain supply regions might translate to ~US$1.00–1.20/m for a comparable rPET twill, again ~10–30% higher, depending on MOQ, finishing, dye route, duties, and logistics. Expect additional line-items for GRS/traceability, lab test reports, and, where applicable, brand sustainability programs.

Tip for buyers:

Push your mills on scale (rPET runs at standard dye lots), shared greige platforms, and finishing parity to compress the premium. In many categories, the total garment or product COGS delta narrows to a few percent, often defensible for sustainability claims.

Application guidance: where each option shines

Fashion & athleisure

For shirts, pants, skirts, athleisure, and light outerwear, rPET twill matches virgin for handfeel, drape, and quick-dry. Most brands can switch to recycled at parity performance if GSM and finishing are held constant.

Uniforms & workwear

Workwear twills (often poly/cotton blends) depend on abrasion, seam strength, and finish durability.

Recycled-content twills from reputable mills now meet common workwear specs while offering a reduced footprint look for vendors with protective/work portfolios and proven finish systems.

For high-wear zones, specify higher GSM or localized reinforcements and lock down test methods in the PO.

Outdoor gear & technical fabrics

Backpacks, shells, and tents use twills and laminates where tear/UV/waterproofing matters. High-end rPET technical lines (including recycled laminates) demonstrate equal or better UV stability claims and robust field life when paired with proper coatings/laminations.

If you’re sourcing coated or laminated twills, vet hydrostatic head, UV stability, and delamination cycles as primary decision points.

Upholstery & home

Commercial upholstery emphasizes double-rub counts, flame compliance, stain release, and shade continuity.

rPET twill can work well, but for extreme abrasion specs, virgin remains more common today.

If choosing recycled, specify higher weave density, performance finishes, and validate via Martindale/Wyzenbeek to your end-use target.

Spec checklist for your RFQ

- Construction: Twill type (e.g., 2/1, 3/1), ends/picks per inch (EPI/PPI), GSM target (± tolerances).

- Yarn: Filament vs. spun, denier/tex, tenacity grade; recycled content % and source type (post-consumer vs. post-industrial).

- Finishes: Anti-pilling, stain release, WR, FR (if needed), UV-stabilized; specify AATCC/ISO methods for validation.

- Mechanical tests:

- Tensile: ASTM D5034 / ISO 13934-1 (strip) targets.

- Tear: ASTM D1424 (Elmendorf) or ISO 13937-2 targets.

- Abrasion: ASTM D4966 (Martindale) or ASTM D4157 (Wyzenbeek) cycles to first yarn break/pilling note.

- Pilling: ASTM D4970 / ISO 12945 rating after set cycles.

- Tensile: ASTM D5034 / ISO 13934-1 (strip) targets.

- Colorfastness: Washing (ISO 105-C06), rubbing (ISO 105-X12), light (ISO 105-B02) grades.

- Compliance & traceability (rPET): GRS/transaction certificates, batch-level traceability, recycled content declaration on COA.

- Quality tolerances: Shade band acceptance, bow/skew, width, shrinkage, and handfeel notes.

- Lot size & logistics: MOQ by shade, lead time, lab-dip/strike-off process, packaging, and inspection plan.

These parameters will influence performance far more than “recycled vs. virgin” in isolation and help ensure apples-to-apples quotes.

Quick comparison summary

- Strength: Virgin = High; rPET = High, typically ~8–10% lower tensile on like-for-like constructions.

- Abrasion: Both are strong; rPET may show slightly earlier mass loss/fuzz under severe rub finishes ,and density can offset.

- Colorfastness/UV: Comparable; both resist fading; aging studies show similar or slightly better retention for rPET in some conditions.

- Cost: rPET twill commands a ~10–30% fabric price premium (driven by fiber + certification).

- Strength: Virgin = High; rPET = High, typically ~8–10% lower tensile on like-for-like constructions.

FAQs

1) Will recycled polyester twill fail faster in workwear?

Not if you specify it correctly. For heavy-wear zones, boost GSM, tighten the twill, and apply anti-pilling/WR finishes. Well-specified rPET twills clear common uniform requirements with lifespans comparable to virgin.

2) How big is the real cost delta in finished goods?

At the fabric level, expect ~10–30% higher for rPET twill; in a finished garment or bag, that often compresses to a low single-digit % of COGS, frequently offset by sustainability positioning.

3) Is color consistency harder with recycled?

Colorfastness is comparable; color consistency depends on mill process control. Insist on shade bands, approved lab dips, and lot-tracking (GRS batch IDs) to maintain continuity.

4) Where should I still choose Virgin?

When you’re at the edge of extreme abrasion or maximum load with little safety margin, virgin can offer a small performance buffer. Even then, try higher GSM/finishes on rPET and test many specs now pass with recycled.

Contact Information

- Mon - Sat: 10:00am-7:00pm

- 4/32-33 Triveni Nagar , Meerpur Cantt , Kanpur-208004

- +91 9839708040 | +91 9936159591

- gncfabrics@gmail.com

Quick Links

- About Us

- Products

- Blog

- Contact Us

© 2024 GNC EXPORTS, All rights reserved. Developed by DIGI PEXEL

- Privacy Policy

- Terms & Conditions

- Cookies Policy