The Ultimate Guide to Duck Canvas Cotton Fabric: From Weight to Weave

Why Duck Canvas is the Unsung Hero of Durable Fabrics

Look down at your feet. If you’re wearing a pair of classic Chuck Taylors, you’re standing on history. That tough material? It’s not just generic cloth. It’s duck canvas cotton fabric.

From that indestructible tote bag you use for groceries to the work jacket that refuses to tear, this fabric is the backbone of durability. But here’s the funny thing—most people have no idea what makes it special.

So, is it just “canvas” with a fancy name? Not exactly.

The term actually comes from the Dutch word “doek”, which means linen cloth. Sailors used it ages ago for sails because it was tough enough to handle gale-force winds without ripping source. Unlike regular canvas, cotton duck canvas is woven tightly with two twisted yarns (plied yarns) instead of just one.

That makes it smoother. It makes it stronger. And it makes it perfect for everything from heavy duty cotton canvas tarps to high-end backpacks.

If you are trying to pick the right material for a project, the options can get confusing fast. You’ve got numbered grades, ounces per yard, and different weaves. Experts like GNC Exports handle these specs daily for industrial clients, but for the rest of us, it can feel like a secret code.

We’re going to fix that. Let’s figure out exactly what this fabric is and how to use it.

What is Duck Canvas? A Deep Dive into the Weave

You might be asking yourself, “Does this have anything to do with the bird?”

Kind of. But not really.

The story starts way back with Dutch sailors. They needed sails and clothes that could handle storms without falling apart. They called this tough linen cloth “doek”.

The fabric was legendary for blocking the wind. Later, when the fabric arrived in English-speaking places, people heard “duck” instead of “doek.” Manufacturers even started stamping a small picture of a duck on the bolts of fabric to show how heavy it was history of the term.

That little stamp became the standard.

But let’s look closer at the fabric itself. Because what is duck fabric really?

It is a type of plain-weave canvas. But it is not the same as the stuff you buy at a craft store for painting.

Generic canvas usually has a simple weave. One thread goes over, one thread goes under. It is rough and bumpy.

Cotton duck canvas changes the game. It uses a special trick in the weaving process. It typically groups two yarns together in the warp (the vertical threads) and weaves them against a single yarn in the weft (the horizontal threads).

This creates a few huge advantages:

- It is smoother. Regular canvas feels gritty. Duck canvas feels like a smooth, hard shield. This means it won’t snag on sharp objects as easily.

- It is tighter. The threads are packed so closely that water has a hard time soaking through quickly. It is naturally water-resistant before you even add wax.

- It is stronger. Those twisted, plied yarns act like a double muscle.

And here is the best part. It is almost always 100% cotton.

You might think heavy duty cotton canvas would be hot and sweaty like plastic or nylon tarps. But because it is natural cotton, it breathes. Air can get through, but wind and dirt get stopped cold.

That is why you see it on everything from construction sites to fashion runways. It feels premium, but it acts like armor.

So, we know it is tough. But did you know there is a system to measure just how tough? It involves some confusing numbers, but we will crack that code next.

The Numbered Duck System: Decoding Fabric Weights and Grades

Okay, let’s look at the numbers. This is where things get a little backward.

Usually, when we count up, things get bigger. But with numbered duck canvas, it works in reverse. It’s confusing, I know. I had to double-check the chart the first time I saw it, too.

In this system, the lower the number, the heavier and tougher the fabric is. A #1 duck canvas is an absolute beast. A #12 duck canvas is much lighter and softer. It is a lot like measuring wire thickness or knitting needles—sometimes the small numbers mean serious business.

This system (which has been around since the 1920s) helps manufacturers know exactly how much weight is packed into the cloth. It is based on a standard bolt width, but we won’t bore you with the math.

What matters is knowing which number fits your project. Here is the cheat sheet you need to crack the code:

Grade | Weight (Approx.) | What It Feels Like | Best Used For |

#1 | ~18 oz/sq yd | Stiff as a board. Hard to fold. | Heavy bags, cots, hammocks |

#4 | ~15 oz/sq yd | Very thick. Rugged. | Sea bags, large equipment covers |

#6 | ~13 oz/sq yd | Tough but manageable. | Utility bags, work aprons |

#8 | ~11 oz/sq yd | Strong but flexible. | Backpacks, tote bags |

#10 | ~9 oz/sq yd | Closer to denim weight. | 10 oz duck canvas, artist canvas, work clothes |

#12 | ~7 oz/sq yd | Softest of the bunch. | Light clothing, jacket liners |

Most of the time, if you pick up a really nice tote bag at a store, you are probably holding #8 duck. It holds its shape so the bag stands up on its own, but it won’t scrape your skin off when you carry it.

But wait, there is one more trap to avoid.

Sometimes you will see fabric just labeled “canvas” without a number. Or it might be called “Single Fill.” Watch out for that.

Real numbered duck canvas uses those twisted (plied) yarns we talked about earlier. “Single fill” usually means they used just one yarn instead of twisting two together. It is cheaper, sure. But it is nowhere near as strong source. If you need durability, stick to the numbers.

Choosing the wrong number can actually ruin a project.

Imagine trying to sew a shirt out of #1 duck. It would feel like wearing a cardboard box. On the flip side, if you try to make a sandbag out of #12, it might burst after a week of use. Durability relies on weight.

For big jobs, getting this spec right isn’t just about feel—it’s about safety and performance.

If a factory needs 5,000 yards of heavy duty cotton canvas for industrial curtains or welding screens, they can’t just guess. They need to know if they are getting a #4 or a #6. That is why experts like GNC Exports are so important for businesses. They ensure that if you order a specific numbered duck—maybe even one treated to be water-resistant or flame-retardant—you get exactly that grade. You don’t want to leave those specs to chance.

So, the rule of thumb? Lower number equals heavy armor. Higher number equals easier to wear.

Key Characteristics and Benefits of Cotton Duck Canvas

So, you know the numbers now. You can tell a #4 from a #10. But why do people actually obsess over this stuff?

It’s not just because it’s strong. I mean, Kevlar is strong, but you wouldn’t make a casual tote bag out of it.

Cotton duck canvas hits a sweet spot. It balances extreme toughness with a natural feel that plastic or synthetic fabrics just can’t match. Here is why it is the go-to choice for everything from workwear to industrial curtains.

It is Built Like a Shield

Remember how we talked about the smooth surface? That matters.

Regular canvas is fuzzy. If you drag it against a brick wall, it catches and tears. Heavy duty cotton canvas is different. Because of that tight, twisted ply weave, it has a flat surface. Friction just slides right off it.

It resists snagging better than almost any other natural fabric. That is why you see it used for coal bags and sandbags. It takes a beating and asks for seconds.

Water Resistant (But Not Waterproof)

Let’s clear up a huge myth. Is it waterproof?

Not naturally. If you throw a sheet of raw duck canvas in a lake, it will eventually soak through. But, it is naturally water-resistant.

Because the heavy threads are packed so tight, water beads up on the surface at first. It takes a while to soak in. Plus, when the cotton fibers get wet, they swell up. This closes the tiny gaps in the weave even more, making it harder for water to pass through.

But here is where the pros take it to another level.

If you need something that is totally rot-proof or waterproof—like for outdoor awnings or marine gear—you can’t just rely on the raw weave. You need treated fabric. This is where industrial experts like GNC Exports come in. They take that raw base and apply wax, oil, or chemical finishes to turn it into a weather-proof fortress.

It Ages Like Fine Wine

This is my favorite part.

Plastic tarps crack. Nylon rips. But duck fabric develops a “patina.”

Just like a good pair of raw denim jeans or a leather jacket, this fabric breaks in over time. It gets softer without losing strength. It develops crease lines that tell a story. That is why fashion brands love using it for jackets and bags—it actually looks better the older it gets.

A Quick Note on Sewing

If you are planning on sewing with duck canvas yourself, I have a warning for you.

Don’t use your standard needle. You will break it. (I’ve snapped three in one afternoon, and it’s not fun).

You usually need a denim needle or a size 100/16 to punch through those dense layers. It is tough stuff to work with, but the result is worth the struggle.

Want to see how this fabric actually moves and behaves in real life? Check out this breakdown:

Now that you know what it is and how it behaves, you are probably wondering: “Okay, but which one do I actually buy?” Let’s break down the specific uses for each type so you don’t waste money on the wrong grade.

Popular Uses and Project Ideas for Duck Canvas

So, we know the grades. We know the history. But what do people actually make with this stuff?

You might be thinking it is only for tents or sailboat repairs. Nope. Actually, you probably see duck canvas cotton fabric every single day without realizing it.

From the job site to the living room, this material is everywhere. Here is how people are using it right now.

1. Workwear That Won’t Quit

You know those brown work jackets that seem to last for twenty years? The ones construction workers and farmers swear by? That is almost always duck canvas.

Brands use heavy duty cotton canvas—usually around 12oz—because it acts like a second skin. It protects you from scrapes, sparks, and wind.

Companies like DRI DUCK use what they call “concrete canvas” to make jackets that compete with the big names source. It starts off feeling a bit stiff. Like, really stiff. But after a few weeks of wear, it breaks in and fits you perfectly. Structured hats and chore coats are great projects if you want to try sewing clothing yourself.

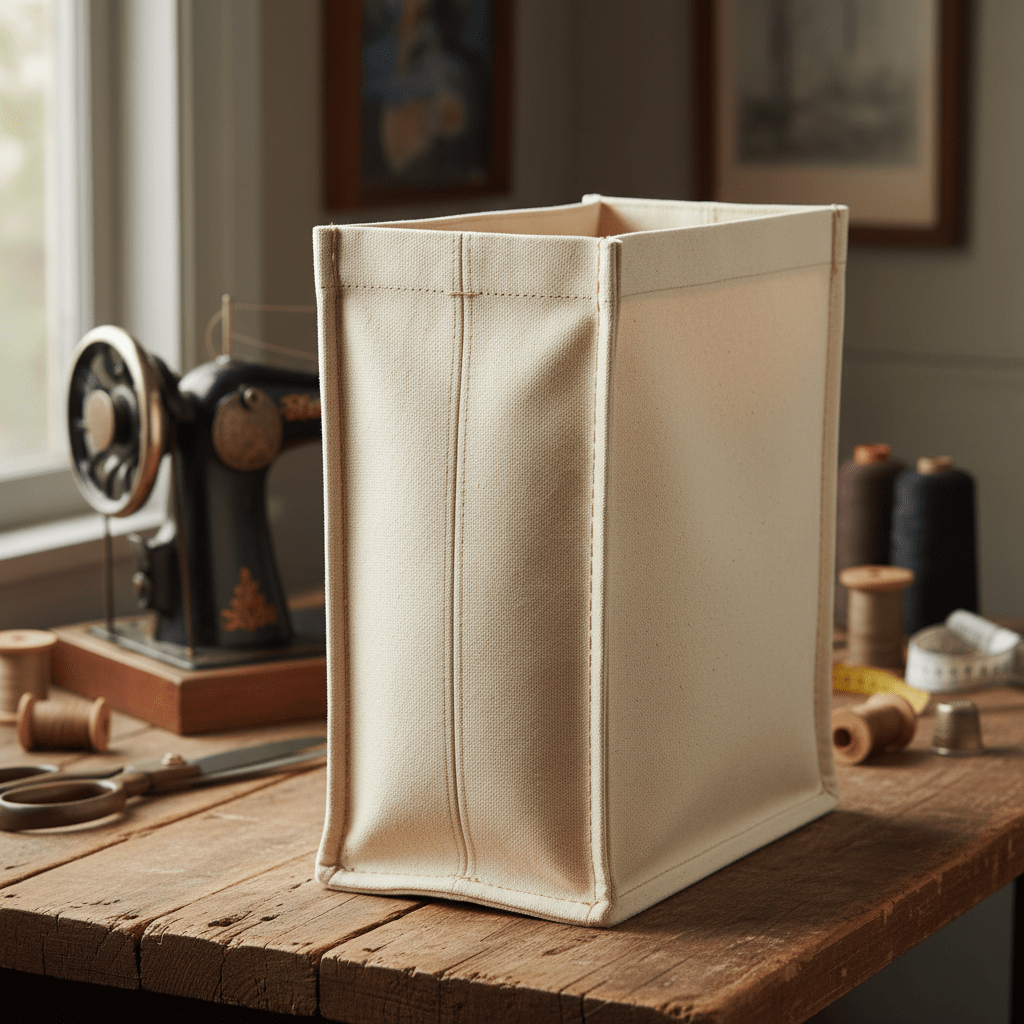

2. Bags and Accessories

This is where uses for duck canvas really shine. Since the fabric is stiff, it holds its shape. If you set a canvas tote bag on the floor, it stays standing. It doesn’t flop over like a thin cotton sack.

High-end brands love this stuff. Take GORUCK, for example. They use heavy waxed duck canvas (up to 18oz) for backpacks that can survive just about anything source.

If you are a beginner, try making:

- Simple Tote Bags: A classic #8 or 10 oz duck canvas is perfect here. It is easy to sew but looks professional.

- Tool Rolls: Keep your wrenches organized. The fabric won’t rip when sharp tools poke it.

- Dopp Kits: A fancy name for a travel toiletry bag. Water resistance is a big plus here.

3. Home Decor and Upholstery

If you have kids or pets, listen up. Upholstery canvas fabric might be the answer to your prayers.

Because it is so tightly woven, pet hair doesn’t stick to it as easily as other fabrics. And if someone spills juice? It usually beads up long enough for you to wipe it away.

People use it for slipcovers on sofas, durable cushion covers, and even floor cloths (think of a heavy rug that you can paint). It gives a room a nice, natural farmhouse look that feels cozy but can take a beating.

Scaling Up for Business

Now, if you are just making one tote bag, you can buy a few yards online. But what if you are a business trying to make 5,000 of them?

That is a different ball game. You need consistency. You can’t have one roll be a #8 and the next one be a #10.

This is where industrial partners like GNC Exports step in. They don’t just sell the raw cloth; they can treat it for you. Need a fire-retardant finish for welding screens? They do that. Need a specific colored wax coating for a line of fashion backpacks? They handle that too.

Getting the specs right at the factory level stops you from having a disaster later on.

So, whether you are sewing a single apron in your garage or managing a supply chain for a clothing brand, this fabric does the work.

Duck Cloth vs. Canvas, Twill, and Denim: A Comparative Analysis

Confused yet? I don’t blame you.

When you walk into a fabric shop or browse online suppliers, everything looks kind of similar. It’s all heavy. It’s all cotton. It all looks tough.

But mixing these up is a rookie mistake. I’ve seen people try to make “jeans” out of cotton duck canvas and end up with pants that stand up on their own (and not in a good way).

Let’s break down the differences so you know exactly what you’re buying.

Duck Cloth vs. Standard Canvas

We touched on this earlier, but it’s the most common mix-up. People use the words interchangeably, but the battle of duck cloth vs canvas has a clear winner.

Think of it like this: Standard canvas is like a rough dirt road. Cotton duck canvas is a paved highway.

- Standard Canvas: Uses a “single fill” weave. One thread goes over, one goes under. It feels bumpy and rough to the touch. It’s great for cheap tote bags or kids’ crafts, but it lacks structural integrity.

- Duck Canvas: Uses two twisted yarns woven together. This makes the surface smooth and dense. Because it’s so tight, it prints better and repels water better source.

If you need something that feels premium and lasts years, skip the plain stuff.

Duck vs. Twill (The Diagonal Factor)

Look at the pants you are wearing right now. (Unless you’re in sweatpants—no judgment here).

If you are wearing chinos or khakis, look closely at the fabric. See those tiny diagonal lines running across your leg? That is Twill.

Twill is woven to be flexible. It drapes over your body comfortably. It’s soft.

Duck canvas, on the other hand, is a plain weave. It looks like a tiny checkerboard. There are no diagonal lines. This structure makes it stiffer and harder. It doesn’t want to drape; it wants to create a structure.

- Use Twill for: Pants, shirts, comfortable jackets.

- Use Duck for: Tents, sturdy backpacks, work aprons, upholstery.

Duck vs. Denim

Here is the one that trips everyone up. Isn’t denim just heavy cotton too?

Yes, but denim is actually a type of twill.

The biggest difference is the color. With denim, the vertical threads are dyed (usually blue) and the horizontal threads are left white. That is why jeans look lighter on the inside. As you wear them, the dye rubs off in a specific pattern.

Heavy duty cotton canvas is usually dyed one solid color all the way through. It holds its color longer and doesn’t get that “whiskered” look that jeans do. It just gets softer.

So, if you want that classic workwear look that stays solid, go with duck. If you want the diagonals and the fade, go with denim.

Finding the exact weave you need—especially for industrial jobs—can be a headache. You don’t want to order 500 yards of “canvas” and get the bumpy single-fill stuff by mistake.

This is why companies partner with specialists like GNC Exports. They know the difference between a 2×1 weave and a standard twill, ensuring your manufacturing line doesn’t stall out because of a fabric mismatch. Whether it’s 10 oz duck canvas or heavy #1 grade, precision matters.

Now that we have the definitions sorted, we need to talk about care. Because if you throw this stuff in a hot washer, you might cry.

How to Sew and Care for Your Duck Canvas Fabric

So, you’ve picked your grade. You have your fabric. Now, what do you do with it?

If you treat heavy duty cotton canvas like a regular cotton sheet, you are going to have a bad time. I learned this the hard way when I tried to sew a bag with a standard needle. The needle snapped, hit me in the safety glasses (wear them!), and I had to start over.

Sewing with duck canvas requires a different game plan. Here is how to tame the beast without breaking your machine.

Step 1: Wash It First (Seriously)

This is the step everyone wants to skip. Don’t.

Raw cotton shrinks. A lot. In fact, untreated duck can shrink between 5% and 8% during its first wash source.

Imagine spending ten hours sewing a perfect jacket, washing it once, and then realizing it now fits your six-year-old nephew. To stop this, throw the fabric in the washer on hot and dry it on high before you make a single cut. Get the shrinking out of the way early.

Step 2: Beef Up Your Tools

Your standard sewing setup won’t cut it. To push through those tight, twisted yarns, you need power.

- The Needle: Swap your standard universal needle for a Jeans/Denim needle. Look for size 100/16 or 90/14. These are sharper and thicker, so they won’t bend when they hit the fabric.

- The Thread: Cotton thread might snap. Use a heavy-duty polyester or a cotton-wrapped poly thread. It needs to be as tough as the bag you are making.

- The Foot: If your machine struggles to pull the thick fabric through, a “walking foot” attachment helps feed the layers evenly.

Step 3: Keep It Clean (The Right Way)

Once your project is finished, you want it to last.

Since duck canvas cotton fabric is naturally tough, you don’t need to baby it too much. But you should usually stick to cold water and a mild soap.

Here is a pro tip: Skip the fabric softener.

Softener works by coating fibers to make them slippery and fluffy. But for canvas, you want that stiff, structured feel. Softeners can mess with the fabric’s natural durability and any water resistance it has. Just wash it and hang it up to air dry.

For the Big Jobs

Now, if you are running a business, you probably don’t have time to pre-wash 500 yards of fabric in a laundry room.

This is where sourcing matters. Industrial partners like GNC Exports often handle the treatments before the fabric even gets to you. Whether you need pre-shrunk material, water resistant canvas, or flame-proof coatings for safety gear, getting the factory to do the hard work saves you a massive headache later.

Treat the fabric right, and it will probably outlast anything else in your closet.# Choosing the Right Duck Canvas for Your Next Masterpiece

So, here we are. We have talked about Dutch sailors. We have done the backward math of the numbered system. We even talked about why your sewing needle hates you.

But at the end of the day, picking the right duck canvas cotton fabric shouldn’t feel like a science test. It really comes down to one question: What does this project need to survive?

If it just needs to look cool and hold some groceries, you don’t need bulletproof armor. If it needs to cover a welding station, don’t buy the soft stuff.

To make it easy, here is a quick decision tree to help you choose:

- “I want to make a light jacket or a bag liner.”

- Grab #12 duck (about 7 oz). It is soft enough to wear but deals with friction better than plain cotton.

- “I’m making a tote bag, artist canvas, or a shop apron.”

- Look for 10 oz duck canvas or #8. This is the gold standard for most gear. It stands up on its own but won’t break your fingers to fold.

- “I need a tarp or sea bag that will outlive me.”

- Go for the heavy duty cotton canvas grades like #4 or #1. Just remember, this is serious industrial material source.

It really is that simple.

And hey, if you are planning something bigger—maybe a full production run of safety curtains or a thousand custom backpack designs—don’t try to figure out the treatments alone. You need consistent quality. Industrial partners like GNC Exports can supply the specific, treated yardage you need so you don’t have to guess about fire ratings or waterproofing.

Whether you are stitching a single bag in your living room or sourcing for a factory, this fabric is worth the effort. It is honest, it is tough, and it only gets better with age.

Now, go thread that machine (with the right needle!) and make something that lasts.

Contact Information

- Mon - Sat: 10:00am-7:00pm

- 4/32-33 Triveni Nagar , Meerpur Cantt , Kanpur-208004

- +91 9839708040 | +91 9936159591

- gncfabrics@gmail.com

Quick Links

- About Us

- Products

- Blog

- Contact Us

© 2024 GNC EXPORTS, All rights reserved. Developed by DIGI PEXEL

- Privacy Policy

- Terms & Conditions

- Cookies Policy