Certifications for Industrial Work Wear Fabric: Complete Buyer Guide

Industrial Work Wear Fabric has one job: protect people while staying compliant with the rules your customers, auditors, and regulators expect you to follow. At the consideration stage, the difference between “looks good” and “fit for purpose” is proof—namely, certifications.

In this guide, you’ll get a clear, practical view of the most important standards, what each one means in the real world, and how to evaluate documentation with confidence.

The certification overview and definitions below are aligned to the source brief you shared.

Why certifications matter in B2B decisions

When you’re supplying garments to oil & gas, utilities, welding shops, airports, warehousing, mining, or construction, compliance is a contractual requirement. The right certificates:

- Prove your fabric’s performance (fire, flash fire, visibility, antistatic, durability, chemical safety)

- Speed up approvals with HSE teams and notified bodies

- Reduce liability by matching the hazard to the correct standard

- Protect margins by avoiding returns and rework when audits happen

If you’re sourcing fabrics or finished goods from partners, insist on valid test reports, current certificates, and clearly scoped products (base fabric, garment, components). We’ll show you what to check later in this guide.

The core certifications for Work Wear Fabric

1) OEKO-TEX® Standard 100 — Chemical safety and skin contact

What it covers: Limits on harmful substances such as formaldehyde, heavy metals, pesticides, allergenic dyes, and volatile compounds.

Why it matters: Workers wear PPE for many hours. OEKO-TEX Standard 100 helps ensure materials are skin-safe and aligned to chemical safety expectations across regions (e.g., EU REACH restricted substances).

Use it when: You need reassurance that the textile is free from hazardous residues and is safe for end users over prolonged wear.

2) ISO 11612 — Heat & flame resistant protective clothing

What it covers: Performance against limited flame spread, convective heat, radiant heat, and molten metal splash (e.g., aluminum, iron). The standard sets levels (e.g., A1/A2 for flame spread; B1–B3 for convective; C1–C4 for radiant) that correspond to hazard severity.

Why it matters: In oil & gas, metalworking, foundries, and emergency response, garments must not continue to burn or melt after the flame source is removed.

Use it when: Exposure to heat and short flame contact is a primary risk; often a legal expectation in many geographies.

3) ISO 11611 — Welding and allied processes

What it covers: Apparel for welders and anyone exposed to sparks, spatter, brief flame contact, and low-voltage incidental shock. Two performance classes:

- Class 1 for lower levels of spatter and heat

- Class 2 for higher-intensity welding operations

Why it matters: Welding risks are specific: spatter and short flame exposure demand fabrics that resist ignition and minimize electrical conductivity.

Use it when: Outfitting welding bays, fabrication shops, shipbuilding, or field welding crews. ISO 11611 typically coexists with ISO 11612 flame-spread requirements.

4) EN ISO 20471 / ANSI/ISEA 107 — High-visibility standards

What it covers: Fluorescent background materials and retroreflective tape amounts, placement, and performance. Visibility classes (EN ISO 20471 Class 1–3; ANSI 107 has similar categories) define minimum surface area and design rules.

Why it matters: In road works, airports, yards, ports, and night operations, workers must be seen from all angles under daylight and low-light conditions.

Use it when: Any traffic-exposed or low-visibility environment requires class-appropriate vests, jackets, coveralls, or trousers.

5) EN 1149 — Electrostatic (anti-static) protection

What it covers: Charge dissipation properties so garments don’t build static that could spark ignition in flammable atmospheres. EN 1149-1/-3 detail test methods; EN 1149-5 applies to garment requirements.

Why it matters: Petrochemicals, grain handling, munitions, paint shops, and ATEX zones require fabrics that won’t trigger electrostatic discharge.

Use it when: The work environment has flammable gases, vapors, or dust. Combine with grounding and footwear rules per site safety.

6) NFPA 2112

What it covers: Garments for short-duration, intense flash fire exposure. Certification requires vertical flame tests (e.g., ASTM D6413) and a full-scale instrumented mannequin test (ASTM F1930) with specific predicted body-burn limits.

Why it matters: Many North American oil & gas and chemical facilities mandate NFPA 2112-certified apparel.

Use it when: Serving the U.S. market or global projects that specify NFPA. Clarify “compliance” vs. “certification”—true certification covers the entire garment (fabric, threads, trims) via an accredited third party.

7) ISO 15797 — Industrial laundry durability

What it covers: Garment/fabric tolerance to high-temperature wash (often 75–85 °C) and tunnel drying (~150 °C) with minimal loss of performance (e.g., no shrinkage that breaks seams, no wash-out of FR finishes, no visibility degradation).

Why it matters: Rental programs and professional laundries are standard in heavy industry. If the fabric can’t withstand cleaning, compliance erodes after a few cycles.

Use it when: Your customer outsources washing or cycles garments frequently. Look for the ISO 15797 “PRO” pictogram where applicable.

8) Quality, sustainability & product conformity markings

- ISO 9001 (supplier): Indicates the manufacturer runs a repeatable quality system, reducing batch variability and defects that could jeopardize compliance.

- GOTS / Bluesign® / OEKO-TEX® STeP: Sustainability and chemical-management certifications that support corporate responsibility targets and tenders.

- CE marking (EU PPE Regulation): Not a fabric certificate but a finished-garment conformity marking after type examination against relevant EN/ISO standards (e.g., EN ISO 11612). Having certified fabrics simplifies CE approvals.

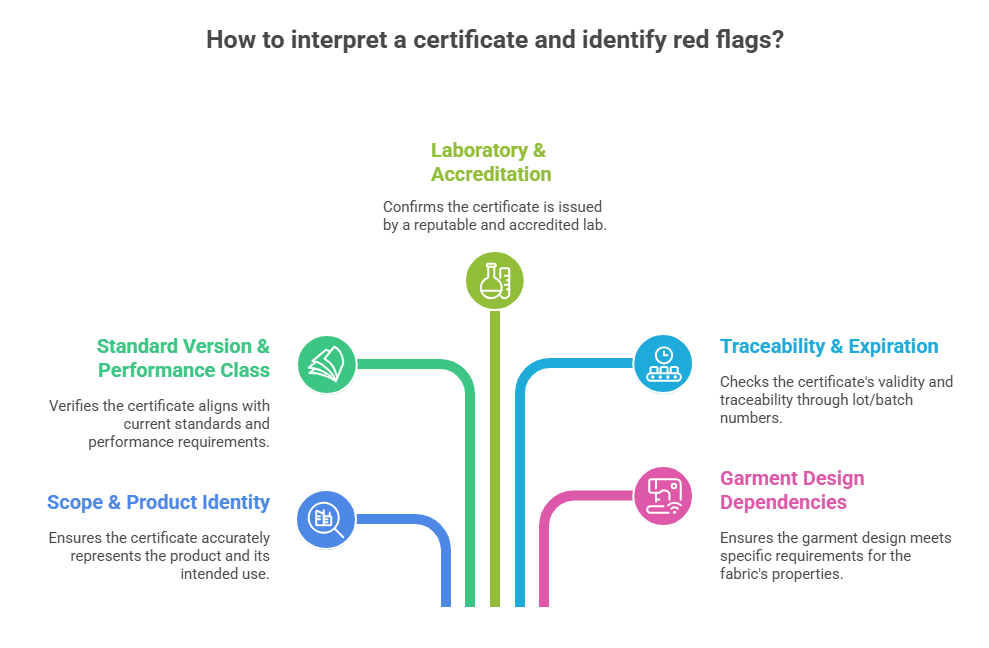

How to read a certificate (and spot red flags)

- Scope & product identity

Does the certificate/test report name your exact fabric (construction, weight, composition, finish), and not a similar “family”?For NFPA 2112: does certification cover the finished garment or just fabric “compliance” language? (They are not the same.)

Certifications for Industrial W… - Standard version & performance class

Check the year/version (e.g., EN ISO 20471:2013 + A1) and class levels (e.g., ISO 11611 Class 1 vs Class 2; ISO 11612 A1/B1/C1 vs higher). - Laboratory & accreditation

Prefer reports from accredited labs; verify lab accreditation numbers and validity online. - Traceability & expiration

Some certificates require surveillance audits or renewals. Ensure the document is current and references lot/batch numbers where relevant. - Garment design dependencies

Antistatic or FR fabrics may require specific construction (proper seam, grounding, compatible threads/tapes). The certificate often assumes correct garment design.

Industry-specific examples

- Oil & Gas / Chemical plants: ISO 11612 for heat/flame; NFPA 2112 for U.S. projects; EN 1149 in ATEX areas; ISO 15797 for harsh laundering; OEKO-TEX for skin safety.

- Welding and fabrication: ISO 11611 (Class 1 or 2 based on process); ISO 11612 for flame spread; ISO 15797 for laundering.

- Road, airport & logistics: EN ISO 20471 / ANSI 107 at the correct visibility Class for the risk; ISO 15797 for service life.

- Grain handling, pharmaceuticals, cleanrooms with flammable solvents: EN 1149 for ESD plus process-specific rules.

- Public tenders in the EU: Ensure final garments meet relevant EN standards and are CE-marked after notified-body assessment.

Maintenance, labeling, and lifespan

Even the best fabric can fall out of compliance if laundered incorrectly. Align your care program with ISO 15797 parameters where applicable, and audit service providers for wash chemistry, temperatures, and drying cycles.

For visibility garments, confirm that retroreflective performance remains within spec after the number of wash cycles stated in the certificate.

Practical buyer checklist

- Hazard mapping: Which risks apply? (heat, welding, flash fire, traffic, ESD, industrial wash)

Standards & classes: Specify ISO 11612 (with required levels), ISO 11611 (Class 1/2), EN ISO 20471 (Class 1–3)/ANSI 107, EN 1149, NFPA 2112 (if U.S.), ISO

15797, OEKO-TEX Standard 100. - Document set: Ask for full test reports, certificates, and garment-level certs where required (NFPA 2112, CE).

- Traceability: Batch/lot references and versioning of standards.

- After-wash performance: Evidence that FR/visibility/ESD properties persist after stated wash cycles.

- Quality & sustainability: ISO 9001, GOTS/Bluesign/STeP as relevant to your tender or CSR policy.

- Pilot test: Run a limited field trial to validate comfort, durability, and serviceability before scaling.

Where to source: start with a compliant partner

If you’re building or refreshing your range, evaluate suppliers who can show complete documentation across the standards you need—and who understand garment construction, not just fabric performance. Explore Work Wear Fabric sourcing and technical support here:

Conclusion

Choosing Work Wear Fabric is a safety decision wrapped inside a sourcing decision. When you align hazards → standards → documented certificates, you protect workers, accelerate approvals, and reduce the total cost of ownership. Use the matrix, flow, and cheat sheet above with your team, and insist on valid, current, and correctly scoped documentation from your suppliers. That’s how you build a compliant, durable, and audit-ready workwear line.

FAQs: Work Wear Fabric Certifications

1) What’s the difference between ISO 11612 and NFPA 2112?

ISO 11612 is a global standard for garments protecting against heat and flame with graded performance levels (e.g., A1/B1/C1). NFPA 2112 is a U.S. certification focused on short-duration flash fire with stringent, mannequin-based burn testing. If you supply to U.S. oil & gas, NFPA 2112-certified garments are often mandatory; for global projects, ISO 11612 is commonly specified.

2) Which high-visibility class do I need for road or airport work?

Match the risk and viewing distance to the class. For high-risk traffic or night operations, choose EN ISO 20471 Class 3 (or the equivalent high category in ANSI/ISEA 107). Yard, warehouse, or lower-speed environments may accept Class 2. Always validate with site HSE rules and tender specifications.

3) How many washes can high-visibility garments withstand and still stay compliant?

It depends on the certificate’s declared wash cycles and your laundry method. Look for EN ISO 20471 reports that show performance after X washes. If you use industrial laundering, confirm fabrics/garments are validated to ISO 15797 (high-temp wash and tunnel dry) so brightness and retroreflective values remain in spec.

4) Does OEKO-TEX® Standard 100 replace chemical compliance like REACH?

No—think of OEKO-TEX Standard 100 as a product-level assurance that the textile is tested for harmful substances. It supports compliance conversations but doesn’t replace legal duties under frameworks like EU REACH. Keep both in mind: OEKO-TEX for skin safety signals, REACH for regulatory obligations across the supply chain.

5) Can ISO 15797 industrial laundering damage FR finishes over time?

If the fabric and chemistry aren’t compatible, yes. Choose FR fabrics validated to ISO 15797 and use the detergents/temperatures specified by the mill. Include a periodic after-wash test protocol (e.g., limited flame spread checks) in rental contracts to ensure FR performance remains within standard after declared cycles.

6) What does ISO 11611 Class 2 actually protect against?

Class 2 is intended for higher welding risk—greater spatter and heat—than Class 1. For heavy MIG/MAG or flux-core processes, Class 2 is typically recommended. Many users also pair ISO 11611 with ISO 11612 (heat/flame) for broader coverage.

Contact Information

- Mon - Sat: 10:00am-7:00pm

- 4/32-33 Triveni Nagar , Meerpur Cantt , Kanpur-208004

- +91 9839708040 | +91 9936159591

- gncfabrics@gmail.com

Quick Links

- About Us

- Products

- Blog

- Contact Us

© 2024 GNC EXPORTS, All rights reserved. Developed by DIGI PEXEL

- Privacy Policy

- Terms & Conditions

- Cookies Policy