Cotton Canvas Fabric vs. Synthetic Fabrics: An In-Depth Comparison for Your Next Project

The Enduring Debate: Natural Cotton Canvas vs. Modern Synthetics

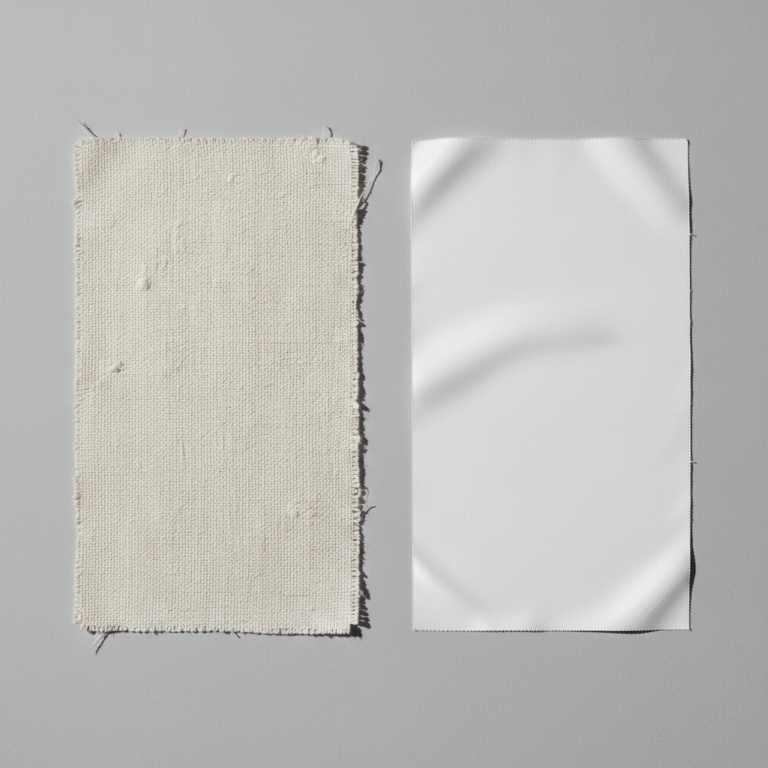

You know that feeling when you’re staring at two fabric swatches, totally stuck?

In your left hand, there’s a piece of heavy duty cotton canvas. It feels thick. Substantial. It reminds you of old military gear or a well-worn field jacket.

In your right hand? A swatch of high-tech synthetic material. It’s light, slick, and promises to last forever.

This is the dilemma every creator faces eventually.

It’s not just about picking a color. It’s about choosing a personality for your project.

See, the textile world is absolutely massive—valued at roughly $1.11 trillion in 2024. And while shiny new synthetics flood the market, humble cotton canvas fabric refuses to quit.

Why?

Because it has character. A rugged aesthetic that tells a story the more you use it. Synthetics might look perfect on day one, but canvas looks better on day one thousand.

But let’s be real for a second. Nostalgia doesn’t keep water out or stop rips. That’s where the battle between natural vs synthetic fibers gets heated.

You might be wondering if traditional materials can actually keep up with modern engineering. Or if switching to plastic-based fabrics ruins the vibe of your product.

I’ve been there. I’ve ruined projects by picking the wrong stuff.

So, let’s settle this. We aren’t just listing specs here. We are going to go head-to-head on the stuff that matters: durability, weather-proofing, and even how they impact the planet.

Whether you’re hunting for the best fabric for tote bags or need something tough for industrial covers, we need to look beyond the label. Let’s figure out if cotton canvas material is still the king, or if the canvas vs polyester debate has a new winner.

- Prove your fabric’s performance (fire, flash fire, visibility, antistatic, durability, chemical safety)

- Speed up approvals with HSE teams and notified bodies

- Reduce liability by matching the hazard to the correct standard

- Protect margins by avoiding returns and rework when audits happen

If you’re sourcing fabrics or finished goods from partners, insist on valid test reports, current certificates, and clearly scoped products (base fabric, garment, components). We’ll show you what to check later in this guide.

The Foundation: What Exactly is Cotton Canvas Fabric?

First off, let’s clear something up. When people talk about cotton duck canvas, they aren’t talking about birds.

It sounds weird, right?

But this name actually refers to the specific way the threads are woven together. Imagine a simple checkerboard pattern: one thread goes over, one goes under. Over, under. Over, under.

That simple “plain weave” is the secret sauce.

Because the threads lock together so tightly, the fabric becomes incredibly strong. It resists tearing in a way that regular cotton—like your t-shirt—just can’t match.

I used to think all canvas was basically the same stuff, just different colors. Boy, was I wrong.

The biggest difference is the weight.

In the textile world, we measure this in “ounces per square yard.” And just to make things confusing, the industry uses a numbering system that is basically backwards.

Here is how it actually works:

- Lower Number = Heavier, thicker fabric

- Higher Number = Lighter, softer fabric

It took me a while to memorize this. If you are holding a piece of Number 1 duck, you are holding a beast. That’s heavy duty cotton canvas—about 27 ounces. It’s stiff, tough, and used for heavy industrial stuff like cots or coal bags.

On the other hand, a Number 12 is much friendlier. It weighs about 11.5 ounces. This is what you usually want if you’re looking for the best fabric for tote bags or work jackets.

Here is a quick cheat sheet I wish I had when I started:

Canvas Number | Weight (approx.) | Best Used For |

#1 Duck | 27 oz | Heavy industrial heavy cots, floor cloths |

#4 Duck | 24 oz | Sea bags, heavy duty tarps |

#8 Duck | 18 oz | Backpacks, tents, work clothes |

#10 Duck | 14.75 oz | Artist canvas, slipcovers, shower curtains |

#12 Duck | 11.5 oz | Tote bags, light apparel |

Source: Canvas Numbering System

But wait, isn’t cotton a sponge?

Naturally? Yes.

If you leave raw cotton canvas material out in the rain, it will get heavy and wet pretty fast. The fibers swell up, which actually closes the gaps in the weave (kind of cool), but it’s not exactly waterproof on its own.

That’s why you almost never see raw canvas used for outdoor gear without some help.

Traditionally, people rubbed wax into the fabric. You’ve probably seen those cool waxed canvas jackets that look like they’ve survived a hundred storms. The wax sits on top and sheds water.

But technology has moved on a bit.

Now, companies create waterproof cotton canvas using modern chemistry. They treat the fabric to be resistant to water, mildew, and even fire. This is huge for industrial sites where safety is a big deal.

This is actually a specialty for manufacturers like GNC Exports. They take that classic, sturdy canvas base and apply specialized finishes—like oil wax or fire-retardant coatings—so you get the tough feel of cotton with the performance of a modern shield.

Actually, there is one more type you should know about: “Army Duck.”

It uses finer yarns twisted more tightly together. It repels water better than regular duck just because the weave is so dense.

So, before we even look at plastic fabrics, remember that cotton isn’t just fluffy stuff. It’s engineered to be tough.

The Contenders: A Primer on Key Synthetic Fabrics

If cotton is the grandfather with great stories, synthetics are the tech-savvy grandkids.

They are everywhere now. And I mean everywhere.

The global textile market hit a staggering $1.11 trillion in value recently, and a massive chunk of that is synthetic fiber. While classic cotton holds its ground, plastic-based fabrics have taken over the outdoor gear world.

But before we compare them, we need to learn a new language.

Remember how cotton numbers go backwards (lower is heavier)?

Synthetics are the opposite. They use a system called “Denier,” usually written as a “D.”

- Low D (like 20D): Super thin, like a windbreaker.

- High D (like 1000D): Thick, rugged, heavy duty.

It is much easier to understand than the cotton duck system. A 1000D bag is twice as heavy as a 500D bag. Simple math.

Let’s meet the three main challengers you will run into.

1. Polyester (The Affordable All-Rounder)

You probably own ten things made of this right now.

Polyester is the most common synthetic because it is cheap to make and pretty easy to work with. If you see a standard school backpack, it is likely made of 600D Polyester.

The Good Stuff:

- Sun Protection: It handles UV rays surprisingly well. It won’t fade as fast as nylon.

- Hydrophobic: That’s a fancy word for “hates water.” It dries very fast because it doesn’t soak up moisture like cotton does.

- Price: It keeps project costs down.

The Bad Stuff:

- The Feel: It feels… plastic-y. There is no getting around it.

- Abrasion: It’s okay, but it’s not the toughest kid on the playground.

It works great for general gear, but if you drag it across concrete, it will show scars faster than high-end nylon.

2. Nylon (The Tough Guy)

This is where the nylon vs canvas durability debate usually starts.

Nylon—specifically branded versions like Cordura or Ballistic Nylon—is beastly. It has an incredible strength-to-weight ratio. This is why the military uses it for everything from duffel bags to tactical vests.

In lab tests called “Wyzenbeek tests” (where a machine rubs fabric until it fails), heavy nylon is a top performer.

While a standard 12oz cotton canvas might handle around 6,000 “double rubs” before thinning out, high-end 1000D Nylon often pushes past 8,000 rubs.

The Catch:

Nylon is thirsty. Unless it is coated with special chemicals, it absorbs water. It also hates the sun. Left outside for a summer, UV rays can weaken the fibers significantly.

3. Acrylic (The Outdoor Specialist)

If you have ever sat under a fancy awning at a restaurant, you were probably sitting under acrylic.

Brands like Sunbrella made this famous. It feels a bit softer, almost like a wool blend, but it is 100% synthetic. We often call this synthetic canvas fabric.

Why people love it:

- It basically never fades. The color goes all the way through the fiber, like a carrot (orange all the way through) vs. a radish (red skin, white inside).

- Mold hates it.

Why people skip it:

- It is expensive. Very expensive.

- It lacks the abrasion resistance of heavy nylon or duck canvas.

So, you have the cheap all-rounder (Polyester), the tough-as-nails soldier (Nylon), and the fancy outdoor expert (Acrylic).

But deciding between these and natural vs synthetic fibers isn’t just about stats on a page. It’s about how they handle real life—rain, rocks, and time.

Let’s break down exactly how they compare when the going gets tough.

Head-to-Head #1: Durability, Strength & Abrasion Resistance

“Strong” appeals to everyone. But in the fabric game, “strong” can mean two totally different things.

Are we talking about surviving a knife slash? Or are we talking about being dragged across a parking lot?

Let’s look at the numbers first.

Scientists use machines to torture fabric. Seriously. The “Wyzenbeek test” basically rubs a piece of wire mesh back and forth over the fabric until it breaks.

Here is how the scoreboard looks:

- Heavy Cotton Canvas (12oz): Usually handles around 6,000 “double rubs.”

- High-End Nylon (1000D): Often pushes past 8,000 rubs.

On paper? The plastic-based fabric wins the abrasion war.

This is why military gear shifted toward nylon. It is lighter and takes more friction before wearing a hole. If you are comparing canvas vs polyester or nylon strictly on numbers, synthetics usually take the gold medal.

But numbers don’t tell the whole story.

The “Rip” Factor

Synthetics often cheat a little bit.

Have you ever looked closely at a camping tent? You might see a tiny grid pattern. That is called “ripstop.” Engineers weave thicker threads into the plastic fabric specifically to stop a small hole from becoming a giant tear.

Cotton canvas material does it the old-fashioned way.

It doesn’t have a grid. It just relies on that super dense weave we talked about earlier. Manufacturers like GNC Exports weave these fabrics so tightly that it is incredibly hard to puncture them in the first place.

If you do snag your canvas bag, it usually stays as a small hole. It doesn’t unzip itself like cheap plastic film does.

The Aging Problem (Or Benefit?)

Here is the biggest difference that nobody talks about until it’s too late.

How do these fabrics die?

Because eventually, everything breaks.

When synthetic fabric gets old, the coating—the stuff that makes it waterproof—starts to peel off. We call this delamination. It looks like a bad sunburn. Once that plastic layer cracks, the fabric is brittle and useless. It becomes trash.

Cotton operates differently.

Top-tier heritage brands have built their reputation on this fact. When you beat up heavy duty cotton canvas, it gets softer. It fades. It develops “patina.”

Think about an old pair of jeans vs. an old plastic raincoat. The jeans look cool. The raincoat looks like garbage.

Plus, you can fix canvas. A needle and thread works fine. Trying to sew coated nylon? Good luck. You usually just end up making more holes that leak water.

So, if you need something to survive a bomb blast today, pick high-end nylon. But if you want a project that might actually look better in ten years than it does today? Canvas is the only real choice.

Now, speaking of leaking water… let’s talk about rain.

Head-to-Head #2: Weather Resistance & Water Management

Even the best fabric can fall out of compliance if laundered incorrectly. Align your care program with ISO 15797 parameters where applicable, and audit service providers for wash chemistry, temperatures, and drying cycles.

For visibility garments, confirm that retroreflective performance remains within spec after the number of wash cycles stated in the certificate.

Here is where things get messy.

Durability is great, but if your gear soaks through during a storm, nobody cares how strong the fabric is. You’re just wet and miserable.

When we talk about water, natural vs synthetic fibers act like totally different species.

The Water Test

Synthetics are usually hydrophobic. They hate water.

If you take a piece of raw polyester, water just sits on top. It doesn’t want to go in.

To make it truly waterproof, manufacturers add a coating—usually something called Polyurethane (PU). In the outdoor industry, we measure this with a score called “Hydrostatic Head” (HH).

Basically, if a tube of water 1,000mm tall sits on the fabric and it doesn’t leak, it gets a 1,000mm rating. Most quality backpacking tents hit between 1,000mm and 10,000mm.

Cotton canvas fabric works differently.

Remember how I said untreated cotton is a sponge? It is. But it has a trick up its sleeve. When cotton fibers get wet, they swell. This swelling actually tightens the weave, closing up the tiny holes where water might sneak through.

It’s nature’s way of sealing the hatch.

But let’s be honest—that only works for a light drizzle. For real heavy weather, you need help.

Extreme close-up of water droplets beading on treated waterproof canvas

That’s why you almost never see raw canvas used for outdoor gear without some help.

This is where waterproof cotton canvas comes in. You can go the old-school route with wax (which looks amazing but can be heavy), or you can use modern chemistry.

Suppliers like GNC Exports take that heavy-duty base and treat it with oil waxes or chemical finishes. This gives you the best of both worlds: the rugged feel of cotton, but with water pouring off it like it’s plastic.

The Silent Killer: The Sun

Water is obvious. You feel it immediately. But the sun destroys gear properly slowly.

UV rays act like tiny little knives, chopping up the polymer chains in fabric.

If you leave a nylon tent set up in your backyard for a whole summer, it will likely be brittle by August. You could probably poke a finger through it. Surprisingly, cotton struggles here too—it fades and loses strength over time.

This is where polyester shines (pun intended).

Polyester is incredibly resistant to UV damage. That is why almost all outdoor patio furniture is made from it. It just sits there, baking in the sun, and doesn’t care.

The Funk Factor (Mold & Mildew)

I learned this one the hard way.

I once stored a canvas swag while it was still slightly damp. Two weeks later, I opened it up, and it looked like a science experiment.

Cotton canvas material is organic. It’s food for mold. If you pack it away wet, it will rot.

Synthetics are inert. Mold might grow on the dirt on the fabric, but it won’t eat the plastic itself.

Does that mean canvas is out? No. It just means you have to respect it.

Plus, modern industrial treatments—like the rot-proofing finishes offered by specialized manufacturers—have largely solved this. If you buy treated canvas, you get a lot more wiggle room.

So, if you are lazy with maintenance (no judgment, we are all busy), synthetics are safer. But if you want a material that breathes and handles condensation better, treated canvas is still the heavyweight champ.

Head-to-Head #3: Sustainability & Environmental Impact

We can’t talk about materials today without talking about the planet.

It feels like every label says “eco-friendly” now. But when you peel back the sticker, the truth about natural vs synthetic fibers gets pretty murky.

Here is the dilemma in plain English.

The Dirt on Cotton

The biggest argument for cotton canvas fabric is simple: it comes from the earth.

It’s a plant. If you bury a 100% cotton bag in your garden, it will eventually break down and turn back into soil. It doesn’t sit in a landfill for 500 years like a plastic bottle.

But nature comes at a cost.

Cotton is thirsty. Really thirsty.

Growing enough regular cotton for just one kilogram of fabric can suck up anywhere from 8,000 to 22,000 liters of water. That is a staggering amount of resources for a few yards of cloth.

Plus, conventional farming often uses a lot of pesticides.

This is why organic cotton aims to fix the problem—it bans the nasty chemicals and usually manages water better—but it’s harder to find and costs more.

The Plastic Predicament

Synthetics like polyester seem cleaner on paper. They use way less water to produce.

But let’s not sugarcoat it: you are effectively wearing oil.

Polyester and nylon are petroleum products. They rely on fossil fuel extraction, which isn’t exactly great for the vibes of the planet.

Then there is the invisible problem.

Every time you wash a synthetic jacket or fleece, tiny little fibers break off. These are microplastics. They flush down the drain, slip past filters, and end up in the ocean. Fish eat them. Then we eat the fish. It’s a mess.

Can We Recycle Our Way Out?

You will see a lot of brands bragging about “recycled polyester” (rPET).

It sounds great. taking old water bottles and turning them into backpacks. And it definitely helps reduces waste.

But there is a catch.

Remember those durability coatings we talked about? The ones that make the fabric waterproof?

Once you bond a chemical layer (like PU or PVC) to a fabric, it becomes a nightmare to recycle. You can’t easily separate the plastic coating from the fiber underneath. So, that waterproof gear usually hits a dead end at the trash can.

So, Who Wins?

Honestly? The winner is whatever lasts the longest.

If you buy a cheap eco-tote that rips in three months, that is waste.

But if you source premium, industrial-grade heavy duty cotton canvas—the kind companies like GNC Exports specialize in—and it lasts for twenty years? That is sustainable.

Sometimes the best way to help the environment is to just buy better stuff, less often. Whether you pick canvas vs polyester, make sure it’s built to survive the long haul.

Which Fabric is Best for YOUR Project? Application-Specific Advice

Stop looking at the spec sheets for a second.

Charts and numbers are great, but they don’t tell you how a project feels when it’s done.

I’ve seen people build incredible heavy-duty backpacks out of plastic-based fabrics that look amazing… for about a week. Then they start to fray, peel, or just look “tired.”

I’ve also seen people try to make ultralight hiking gear out of cotton canvas material, and they end up miserable because their pack weighs ten pounds when it rains.

The real secret to winning the canvas vs polyester debate isn’t about which one is “better.” It’s about which one fits the job.

Let’s break this down by what you are actually making.

1. For Daily Use & Fashion (Totes, Aprons, Jackets)

If you are on the hunt for the best fabric for tote bags or workwear, put the calculator away. This is about vibes.

Think about a classic L.L. Bean tote or a Filson jacket. Why do people pay hundreds of dollars for them?

It’s the soul.

Cotton duck canvas has a natural texture that synthetics just can’t fake. When you scratch a polyester bag, it looks damaged. When you scratch a waxed canvas bag, it tells a story. We call this “patina.”

Heritage brands know this. They don’t switch to plastic because their customers want gear that looks better the older it gets.

My Verdict:

- Go with Canvas: If you want style, comfort, or something that ages like fine wine.

- Go with Synthetic: If you need it to weigh absolutely nothing or pack down into a tiny pocket.

2. For the Great Outdoors (Tents, Boats, Tarps)

This is where things get tricky.

If you are covering a boat, the sun is your biggest enemy. UV rays eat nylon for breakfast. For marine covers, you usually want a solution-dyed acrylic (often called synthetic canvas fabric) or a high-grade polyester because they just don’t fade.

But for sleeping? That is a different story.

Have you ever woken up in a nylon tent feeling damp and clammy? That’s condensation. Plastic fabrics trap moisture inside with you. It’s gross.

Waterproof cotton canvas is magical here. Because the fabric breathes, moisture can escape. This is why “glamping” tents are almost always made of canvas. You sleep better.

My Verdict:

- Go with Treated Canvas: For tents where you want comfort, or tarps near fire (synthetics melt instantly).

- Go with Synthetics: For boat covers or backpacking gear where weight is the only thing that matters.

3. For the Hard Work (Tools, Industry, Luggage)

Okay, let’s talk about abuse.

If you are dragging a bag across concrete floors or throwing sharp tools into it, you need armor.

On paper, ballistic nylon wins the nylon vs canvas durability fight. It has higher abrasion resistance numbers. It takes a lot to wear a hole in it.

But here is the catch—once nylon rips, it is usually game over. You can’t really patch it easily without it looking messy or leaking.

Heavy duty cotton canvas is different. It’s the “workhorse” choice.

If you stick a screwdriver through a canvas tool roll, you can sew it shut. It’s repairable. Plus, the grip is better. Canvas has friction; slippery nylon slides all over the backseat of your truck.

Rugged canvas tool roll on a workshop table

This is where sourcing matters a lot. You can’t just grab generic craft store fabric for industrial jobs.

Companies like GNC Exports are crucial here. They don’t just sell “canvas.” They engineer it. They take that heavy #4 or #8 duck and treat it to be fire-resistant, rot-proof, or oil-waxed for specific industrial nightmares.

If you are building something that needs to pass safety codes and survive a construction site, you need that kind of specialized natural vs synthetic fibers blend or treatment.

My Verdict:

- Go with Canvas: For tool rolls, duffels, and industrial covers where you need grip, repairability, or fire resistance.

- Go with Nylon: For luggage that gets thrown by airport handlers, where you just need raw tear strength.

At the end of the day, there is no perfect fabric. Just the right one for right now.

So, what are you building? Because that answers the question for you.

Conclusion: Choosing Between Timeless Tradition and Technical Performance

Look, I wish I could give you a single winner here.

But the honest truth? The “perfect fabric” doesn’t exist.

There is only the fabric that works for your specific headache. The battle between natural vs synthetic fibers isn’t about one being better; it’s about tradeoffs.

Here is your final cheat sheet to make the call:

- Choose Cotton Canvas when: You want gear that develops character, can be repaired with a simple needle, and doesn’t feel like a plastic bag. If you prioritize sustainability and aesthetic, this is it.

- Choose Synthetics when: You are counting every single gram of weight or need gear to sit in a puddle for three days without a specialized coating.

But the line is getting blurry.

We are seeing a massive shift in the industry. The market for technical textiles is projected to hit over $330 billion by 2034, and a lot of that growth is in hybrids—materials that mix the toughness of synthetics with the feel of cotton.

Designers like Vivienne Westwood have famously said, “Buy less, choose well, make it last.” That is the real secret.

Whether you need a fire-retardant cover for a factory or a simple weekend bag, don’t settle for cheap generic stuff that ends up in a landfill.

If you decide that the rugged, repairable path is the one for you, you need a partner who understands the engineering behind the fiber. Specialists like GNC Exports don’t just sell cloth; they treat it to survive the real world.

So, pick the material that fits your story. Then build something that lasts.

Contact Information

- Mon - Sat: 10:00am-7:00pm

- 4/32-33 Triveni Nagar , Meerpur Cantt , Kanpur-208004

- +91 9839708040 | +91 9936159591

- gncfabrics@gmail.com

Quick Links

- About Us

- Products

- Blog

- Contact Us

© 2024 GNC EXPORTS, All rights reserved. Developed by DIGI PEXEL

- Privacy Policy

- Terms & Conditions

- Cookies Policy