Sustainable Textiles: How Recycled Polyester Is Changing the Apparel and Industrial Fabric Industry

Companies today are under pressure to deliver performance, price stability, and credible sustainability. One material keeps showing up in RFPs and supplier conversations: recycled polyester (often called rPET).

We’ll explain what it is, how it’s made, why sustainable polyester fabrics are winning specs in both apparel and industrial applications, and what procurement teams should look for before shortlisting suppliers.

What Is Recycled Polyester?

Recycled polyester is polyester (PET) made from post-consumer and/or post-industrial waste rather than virgin petrochemical feedstock.

Common feedstocks

- Post-consumer: Used PET bottles, thermoform trays, packaging films, and textile waste.

- Post-industrial: Yarn waste, selvage, offcuts, production scrap.

Two main recycling routes

- Mechanical recycling: Waste is sorted, washed, flaked, melted, and re-extruded into chips and filament or spun-staple. It’s widely available and cost-effective, but polymer chains can shorten with each heat cycle.

- Chemical recycling (depolymerization): Breaks PET down to monomers (e.g., BHET/TPA + EG) and rebuilds “like-new” polymer. Higher capex and currently smaller scale, but better for closed-loop quality and repeated recycling.

Result: yarns and fabrics with looks, handfeel, and properties comparable to virgin polyester; now with a recycled content claim that your customers can verify.

Why Sustainable Polyester Fabrics Are Gaining Ground

1) Measurable environmental gains

- Lower fossil dependence: Displaces virgin petrochemical inputs.

- Waste diversion: Converts bottles and textile waste into usable fiber.

- Carbon footprint reductions: LCAs often show lower cradle-to-gate emissions vs. virgin PET (magnitude varies by process and geography).

- Water and energy efficiency: Improvements are process-dependent, but modern lines often deliver better intensity metrics than older virgin PET lines.

2) Performance buyers already trust

Polyester’s inherent strengths: tensile strength, abrasion resistance, dimensional stability, wrinkle resistance, and colorfastness carry over. For many specs, recycled equivalents meet the same standards as virgin.

3) Supply chain alignment with customer demands

Global brands and enterprise buyers are publishing sustainability roadmaps with recycled-content targets. Specifying eco-friendly polyester fabrics gets you aligned with those targets without sacrificing performance or price clarity.

Performance Characteristics That Matter in B2B

When you compare rPET to virgin, evaluate the following: your test methods and tolerances are what procurement will live with:

- Yarn/fiber form: Filament (e.g., 75D–300D) for smooth, high-strength woven/knits; staple/spun for twills, canvases, and blends.

- Breaking strength/elongation: ASTM D5034/D5035 (woven) or ISO equivalents.

- Tear resistance: ASTM D1424 (Elmendorf) or D2261; critical for workwear and coated substrates.

- Abrasion resistance: Martindale or Wyzenbeek for seating, luggage, workwear.

- Pilling & snagging: Especially for knits and brushed surfaces.

- Colorfastness: AATCC/ISO to washing, rubbing, perspiration, and light.

- Thermal behavior: Heat-setting, shrinkage, and dimensional stability in downstream processes (lamination, calendaring, coating).

- Add-ons & finishes: Antimicrobial, wicking, flame-retardant, soil release, UV stabilization, anti-static; confirm compatibility with recycled base.

Regulatory: OEKO-TEX® STANDARD 100, REACH, CA Prop 65, and sector-specific requirements (e.g., FMVSS for auto interiors).

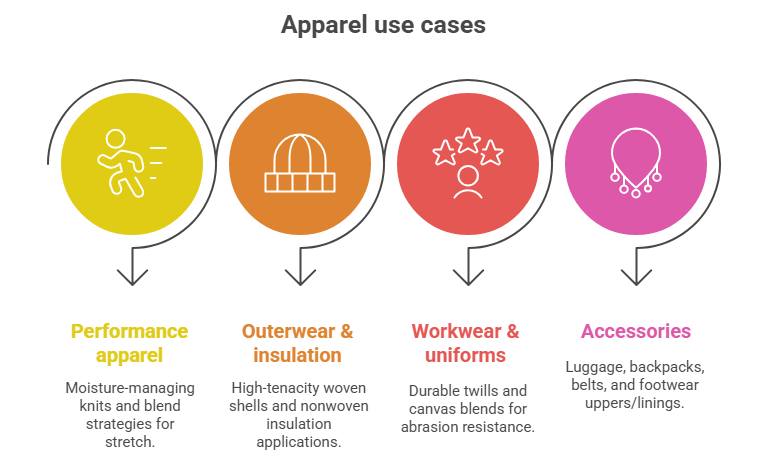

Key Use Cases in Apparel

Performance apparel & athleisure

- Moisture-managing knits, interlocks, and meshes in 50–150 GSM ranges.

- Blend strategies (rPET + elastane) for stretch and recovery.

Outerwear & insulation

- High-tenacity woven shells (e.g., 75D/150D) with DWRs.

- Nonwoven insulation from recycled polyester staple, replacing down or virgin synthetics.

Workwear & uniforms

- Durable twills and canvas blends (rPET/cotton or 100% rPET) for abrasion resistance and easy care.

- Color continuity across seasons with solution-dyed rPET options to reduce water and improve lightfastness.

Accessories

- Luggage, backpacks, belts, and footwear uppers/linings leveraging 300D–1200D rPET with PU or PVC coatings.

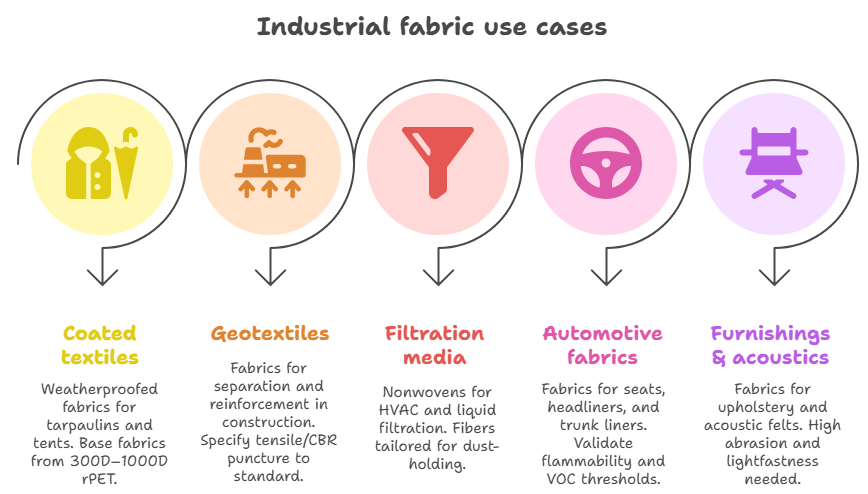

Key Use Cases in Industrial Fabrics

Coated & laminated technical textiles

- Tarpaulins, awnings, tents, architectural membranes: Base fabrics from 300D–1000D rPET; coated or laminated for weatherproofing.

- Advertising banners & signage: rPET base cloths as a lower-impact alternative to virgin PET.

Geotextiles & construction

- Nonwovens and woven geotextiles for separation, filtration, and reinforcement in civil projects; specify tensile/CBR puncture to standard.

Filtration media

- Nonwovens for HVAC and liquid filtration; rPET fibers tailored by denier and crimp for dust-holding and pressure-drop targets.

Automotive & transport

- Seat fabrics, headliners, and trunk liners using rPET face fabrics and felts; validate flammability and VOC thresholds.

Furnishings & acoustics

- Upholstery, panel fabrics, and acoustic felts with high abrasion and lightfastness requirements.

How Recycled Polyester Is Transforming Procurement & Product Innovation

1) Spec-level sustainability without re-engineering the product

Buying teams can hit recycled-content KPIs with minimal changes to patterns, machinery, or quality plans, especially when yarn count, weave pattern, and finishing remain constant.

2) Traceability and claims you can defend

- Certifications: Global Recycled Standard (GRS) and Recycled Claim Standard (RCS) verify recycled content and chain-of-custody. OEKO-TEX® can cover chemical safety.

- Digital traceability: Many mills now offer lot-level trace data and QR-linked certificates, easing B2B audits.

3) Design freedom

- Solution dyeing (dope dye): Pigments added to the polymer for better colorfastness and reduced water/chemicals; popular in luggage/upholstery.

- Functional masterbatches: UV, FR, anti-static, and IR management at the polymer level to reduce post-finishing steps.

4) Portfolio resilience

Qualifying sustainable polyester fabrics from multiple mills across regions can hedge against bottle-flake supply shocks and regulatory shifts.

Challenges & Misconceptions

“rPET is always lower quality.”

Not when you match the process to the application. Mechanical rPET can meet most apparel/industrial specs; chemical recycling can deliver virgin-like polymer for critical uses.

“Color consistency is harder.”

It can be, especially with mechanically recycled streams. Solutions: tight input specs, preferred flake suppliers, solution-dyed programs, or color-management SOPs with delta-E thresholds.

“Microfiber shedding is the same as virgin.”

Shedding depends more on fabric construction and finishing than on recycled vs. virgin status. Choose tighter constructions, apply low-impact finishes, and validate via standard tests.

“Price won’t be competitive.”

Regional dynamics matter. With stable bottle-flake contracts and efficient lines, rPET often competes with virgin, especially where carbon or EPR costs apply.

“Recycled = sustainable, full stop.”

Sustainability is bigger than content claims. Ask about energy mix, water treatment, chemical management, and transport distances; then use LCAs to compare options.

A Buyer’s Quick-Spec Checklist

Use this to speed up Request for Quote (RFQs) and apples-to-apples comparisons:

- Recycled content: % by weight, post-consumer vs. post-industrial; GRS/RCS certificates and lot numbers.

- Recycle route: Mechanical vs. chemical; if chemical, process type and polymer IV target.

- Yarn & construction: Filament/staple, denier/tex, filament count, twist, weave/knit details, GSM.

- Finishes & coatings: DWR type (C0/C6 alternatives), PU/PVC/TPU coating specs, lamination parameters.

- Performance tests: Breaking/tear strength, abrasion (Martindale/Wyzenbeek), colorfastness suite, pilling, dimensional stability, UV, FR, where applicable.

- Compliance: OEKO-TEX®, REACH, specific regional or vertical standards (auto/aviation/building codes).

- Process control: Heat-setting profile, dye method (piece, yarn, solution-dyed), batch size, and deviation limits.

- Traceability: Chain-of-custody documentation, QR/portal access, retained samples policy.

- Commercials: MOQ, lead time, shade cards, continuity program, price-adjustment clauses for flake indexes.

End-of-life: Take-back or closed-loop options; recyclability of coated constructions.

Industry Examples (What We’re Seeing in the Field)

- Sportswear and outdoor brands scaling rPET tees, fleeces, and shells without performance trade-offs; particularly via solution-dyed programs for colorfastness and water reduction.

- Automotive interiors are shifting from nonwovens and some face fabrics to rPET while preserving flammability and VOC limits.

- Furniture and workspace sectors are adopting rPET upholstery and acoustic felts to meet enterprise sustainability RFP criteria.

- Industrial signage and soft infrastructure (awnings, tarps, tents) increasingly use rPET base cloths beneath PU/PVC coatings to reduce virgin content.

Practical Steps to Pilot rPET This Quarter

- Select one or two SKUs with high volume and low regulatory risk (e.g., a 150D Oxford or a 240 GSM knit).

- Dual-source from two mills; one mechanical, one chemical recycling if available.

- Run a lab-to-line validation: Shade, finishing, and performance testing against your current spec.

- Lock traceability early: GRS/RCS paperwork and batch tracking in your PLM/ERP.

- Negotiate continuity: Price-stability clauses tied to agreed flake indices and energy surcharges.

- Communicate the change: Provide your customers with a short tech note summarizing recycled content, test results, and end-of-life guidance.

The Takeaway: Why Adopt Sustainable Polyester Fabrics Now

Sustainable polyester fabrics let you decouple performance from petro-dependence. They fit existing machinery, meet familiar test methods, and align with customers’ sustainability roadmaps.

For apparel, rPET enables durable, colorfast, easy-care garments with credible recycled content claims. For industrial fabrics, it strengthens your bid with traceability and measurable environmental benefits, without forcing a redesign of proven constructions.

Are there challenges? Yes, color control, microfiber management, and supply dynamics all require smart supplier selection and robust QA.

But those are process problems, not material limitations. With the right partners and specifications, eco-friendly polyester fabrics can become a dependable part of your portfolio, helping you hit sustainability targets, maintain margins, and win RFPs in markets that increasingly vote with their environmental criteria.

If you’re mapping your materials roadmap, start with a controlled pilot, validate performance, and scale what works.

And don’t forget to direct readers to your pillar on sustainable textiles and a neutral comparison guide to help buyers make informed, defensible choices.

FAQs

1) What’s the difference between mechanical and chemical recycling, and which should we choose?

Mechanical recycling cleans, flakes, and remelts PET into new chips and yarn. It’s widely available and typically the most cost-effective. Chemical recycling breaks PET back to monomers and rebuilds “like-new” polymer, useful for tighter color/quality demands or multiple recycling loops. Your choice should be driven by end-use: most apparel and many industrial specs are met with mechanical rPET; select chemical routes for critical properties or strict shade continuity.

2) Do sustainable polyester fabrics perform like virgin polyester?

Yes, when the yarn count, construction, and finishing are matched. rPET fabrics routinely meet the same test methods (e.g., tensile/tear, abrasion, colorfastness) used for virgin lines. For high-stress applications, request recent lab data and pilot yardage to validate on your own machines before scaling.

3) How can we verify recycled content and avoid greenwashing?

Ask for GRS or RCS chain-of-custody certificates, lot numbers, and links to digital records on every shipment. Pair this with safety/compliance marks (e.g., OEKO-TEX® STANDARD 100) and keep retained samples. For internal linking, you can point readers to your policy page on sustainable textiles, explaining how you audit suppliers and claims.

4) Will switching to rPET affect price, MOQs, or lead times?

It can, but not always. In many regions, eco-friendly polyester fabrics are at price parity with virgin, especially under stable bottle-flake contracts. MOQs are typically similar; lead times depend on color method (solution-dyed vs. piece-dyed) and finishing queues. Mitigate risk by dual-qualifying mills and adding price-adjustment clauses tied to flake indexes.

5) Does rPET shed more microfibers than virgin polyester?

Microfiber release is driven more by fabric construction and finishing than by recycled vs. virgin status. Tighter weaves/knits, anti-pilling finishes, and robust dye/heat-set processes reduce shedding. Validate with standardized tests and specify care guidelines for apparel or abrasion-prone industrial uses.

Contact Information

- Mon - Sat: 10:00am-7:00pm

- 4/32-33 Triveni Nagar , Meerpur Cantt , Kanpur-208004

- +91 9839708040 | +91 9936159591

- gncfabrics@gmail.com

Quick Links

- About Us

- Products

- Blog

- Contact Us

© 2024 GNC EXPORTS, All rights reserved. Developed by DIGI PEXEL

- Privacy Policy

- Terms & Conditions

- Cookies Policy