What is Recycled Polyester Fabric and Why It Matters for Modern Supply Chains

What if the plastic bottle you tossed yesterday could become the jacket you wear tomorrow?

Over 480 billion plastic bottles made from recycled materials are sold worldwide yearly. Many discarded plastics end up in landfills or oceans, yet some take on a second life, reborn as fabrics made from recycled plastic, worn on your morning run, stretched over your car seat, or draped as curtains in a hotel suite.

This transformation is made possible by recycled polyester fabric, a material quietly reshaping the sustainable textile industry.

The shift towards using recycled materials isn’t driven solely by environmentalists. Global businesses face mounting pressure from investors, consumers, and regulators to reduce their environmental footprint.

What is Recycled Polyester Fabric?

Recycled polyester fabric, often called rPET, is a textile made from recovered plastic waste, often post-consumer PET bottles or post-industrial offcuts from manufacturing.

Unlike virgin polyester, which is made from petroleum-derived raw materials, upcycled polyester gives discarded plastics a valuable second life, contributing to a commitment to sustainability.

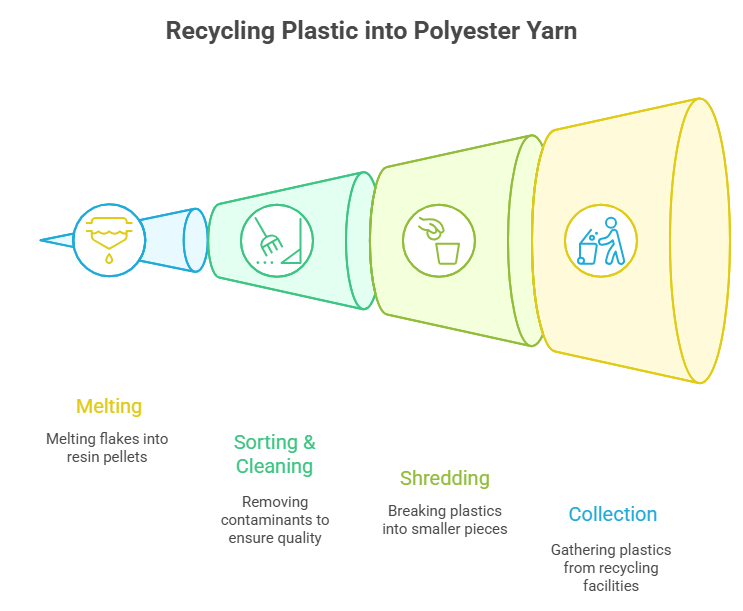

How it’s made:

- Collecting – Discarded plastics are gathered from recycling facilities, ocean clean-up programs, and industrial waste streams to be transformed into recycled polyester yarn.

- Sorting & Cleaning – Contaminants like labels, dirt, and metals are removed to maintain the quality of recycled PET used in polyester recycling.

- Shredding & Melting—Plastics are shredded into flakes and then melted into resin pellets to produce virgin polyester or recycled polyester.

- Extrusion into Fibers is a key process in making recycled polyester for various applications. – Pellets are spun into yarns that are woven or knitted into fabrics.

Why it matters compared to virgin polyester:

- Producing reused polyester uses 30–50% less energy and water than virgin polyester.

- It generates significantly lower greenhouse gas emissions.

- It reduces dependence on virgin fossil fuels and aligns with sustainability goals.

- It diverts waste that would otherwise remain in the environment for centuries.

Benefits of Recycled Polyester Fabric in Modern Supply Chains

1. Environmental Impact You Can Quantify

- Using recycled materials reduces virgin petroleum usage significantly.

- Prevents millions of bottles from ending up in oceans and landfills.

- Enables closed-loop production models, where high-quality textiles made from recycled materials can be recycled repeatedly, reducing pollution.

Example: In 2023, a European sportswear company replaced 80% of its polyester with recycled sources, saving an estimated 40,000 tonnes of CO₂ emissions and preventing over 1 billion bottles from entering waste streams.

2. Cost Efficiency in a Volatile Market

Virgin polyester pricing is tied to global oil markets, which are notoriously unstable. Recycled polyester draws from an alternative raw material pool, providing more predictable pricing.

Additionally, integrating in-house reusing programs can reduce waste disposal costs and even create secondary revenue streams through the benefits of recycled polyester.

3. Durability & Performance Without Sacrifice

Recycled polyester offers the same strength, wrinkle resistance, quick-drying properties, and colour fastness as virgin polyester, making it a preferred choice in the sustainable textile industry.

In applications where performance matters, such as sports uniforms, automotive seat fabrics, or outdoor gear, upcycled options from recycled PET meet or exceed the expected standard for polyester clothing.

4. Certifications for Transparency

Procurement teams can verify the durability claims of eco-friendly products through certifications like the Global Recycled Standard, which includes recycled polyester staple fibre.

- GRS (Global upcycled Standard) – Confirms recycled content, environmental practices, and chemical safety.

- RCS (Recycled Claim Standard) – Verifies the upcycled content percentage in recycled polyester yarn.

- OEKO-TEX® – Certifies safety for human contact by ensuring no harmful chemicals are present in eco-friendly textiles, including those made from recycled polyester.

5. Alignment with Corporate Sustainability Goals

Switching to recycled polyester supports ESG reporting, specifically Scope 3 emissions reductions, by minimizing the need for producing virgin polyester.

It also boosts brand image by showcasing measurable sustainability actions, which is increasingly important for both B2B and B2C relationships.

Industry Applications and Case Studies

Fashion & Apparel

Global brands like Adidas, Patagonia, and H&M have committed to using 100% upcycled polyester by 2030. Adidas’ “Parley” range, for instance, uses yarn spun from ocean-recovered plastics, proving that high performance can coexist with durability in the fashion industry.

Use cases for recycled fabric include polyester clothing that meets the standards of the automotive industry.

- Sportswear that must withstand frequent washing and high movement.

- Fashion items designed for eco-conscious consumers.

- Workwear and uniforms where durability is essential.

Automotive

The automotive sector is under strict sustainability mandates, especially in Europe and North America. Manufacturers like Ford and BMW now incorporate products made from recycled polyester into seat covers, carpets, and trunk linings.

Ford claims that its use of upcycled polyester in interiors has prevented hundreds of millions of bottles made from recycled plastic from entering landfills since 2008.

Home Textiles & Furnishings

Hotels, airlines, and real estate developers are adopting upcycled polyester for curtains, upholstery, and bedding, showcasing its versatility and sustainability.

The material’s stain resistance and easy-care properties make it a cost-effective option for high-traffic environments, while its sustainability credentials align with corporate environmental policies.

Integrating Recycled Polyester into the Supply Chain

Adopting recycled polyester requires more than switching fabrics; it often involves rethinking supplier relationships, product design, and marketing strategies to highlight the versatility of using recycled polyester.

Key considerations for procurement managers:

- Supplier Verification – Work with certified suppliers to ensure authenticity.

- MOQ (Minimum Order Quantities) – Some upcycled polyester options may have higher MOQs; plan inventory accordingly.

- Lead Times – Demand surges can affect delivery; secure supply contracts for high-quality recycled materials early.

- End-of-Life Planning – Build systems for reclaiming and reusing eco-friendly products post-use, focusing on the recycling process of recycled polyester fiber.

Sustainability and Certifications: Why They Matter

In a world increasingly skeptical of “green” marketing claims, third-party verification is crucial. GRS and RCS certifications not only protect against greenwashing accusations but also simplify compliance with global labelling laws.

Market Trends & Future Outlook

- Double-Digit Growth Forecast: Analysts predict the recycled polyester market will grow at over 12% annually through 2030, driven by the increasing demand for sustainable textile solutions.

- Chemical Recycling Innovation: New processes can break polyester back into its base molecules, enabling infinite upcycling without loss of quality.

- Government Mandates: The EU and some US states are introducing reused content requirements in textiles, promoting the use of environmentally friendly materials.

- Consumer Pressure: Surveys show over 60% of consumers prefer brands with proven sustainability credentials in sustainable fashion.

Final Thoughts

Recycled polyester fabric is not just a sustainable alternative; it’s a strategic advantage for supply chains seeking resilience, cost stability, and brand credibility in the fashion industry.

From reducing environmental impact to meeting stringent ESG goals, its benefits are measurable and marketable.

If you’re ready to integrate reused synthetic fabric into your products, explore our product categories or connect with trusted suppliers to review samples, certifications, and long-term sourcing options.

Frequently Asked Questions (FAQs)

1. Is recycled polyester as strong as virgin polyester, especially when considering energy compared to virgin polyester?

Yes. When sourced from quality-certified suppliers, upcycled polyester matches virgin polyester in strength, colour fastness, and longevity.

2. Does reused polyester cost more?

Ans. It can be slightly more expensive in some cases, but price stability and long-term durability ROI often offset the difference.

3. Can upcycled polyester be recycled again through the recycling process to further enhance polyester production in sustainable textile applications?

Ans. Yes, with advanced mechanical and chemical recycling, it can be processed multiple times without significant quality loss.

4. Which certifications should I look for?

Ans. GRS, RCS, and OEKO-TEX® are globally recognized standards that verify sustainability claims.

5. How does recycled polyester, particularly from polyethylene terephthalate, support ESG reporting?

Ans. It provides a tangible way to cut Scope 3 emissions and demonstrate environmental responsibility in sustainability reports, especially through the use of recycled PET.

Contact Information

- Mon - Sat: 10:00am-7:00pm

- 4/32-33 Triveni Nagar , Meerpur Cantt , Kanpur-208004

- +91 9839708040 | +91 9936159591

- gncfabrics@gmail.com

Quick Links

- About Us

- Products

- Blog

- Contact Us

© 2024 GNC EXPORTS, All rights reserved. Developed by DIGI PEXEL

- Privacy Policy

- Terms & Conditions

- Cookies Policy