Wax Coated Fabric vs Oil Wax Fabric: What’s the Difference?

In the world of technical and industrial textiles, the materials you choose can make or break the performance and longevity of your final product.

Whether you’re sourcing durable cotton canvas for outdoor covers or creating premium lifestyle accessories, you’ve likely encountered two similar-sounding but very different materials: Wax Coated Fabric and Oil Wax Fabric.

Though their names are often used interchangeably, they serve distinct purposes. Understanding the nuances between them isn’t just good practice, it’s critical to selecting the right fabric for your end use. So let’s break it down.

What is Wax Coated Fabric?

Wax Coated Fabric typically starts with a strong base material like heavy cotton or canvas. It’s then treated with a solid, dry wax that adheres to the surface, usually through a heat-setting process. This results in a matte finish that feels dry and slightly rigid.

Key Features:

- Dry, structured hand-feel

- Matte, uniform surface

- Breathable and moderately water-repellent

- Minimal patina over time

- Easy to re-wax using solid wax bars

This type of fabric is favored in workwear, industrial bags, and outdoor gear where toughness and low maintenance are priorities.

What is Oil Wax Fabric?

Oil Wax Fabric undergoes a different finishing process. The base fabric is infused with a combination of oil and wax, allowing deeper penetration into the fibers. The result? A supple texture with a luxurious sheen that evolves into a beautiful patina over time.

Key Features:

- Soft, slightly greasy texture

- Glossy, pliable finish

- Enhanced water resistance

- Develops a vintage character with use

- Requires careful storage and professional reconditioning

This fabric is ideal for high-end applications – think fashion bags, jackets, and artisanal accessories that need to stand out visually.

Wax Coated Fabric vs Oil Wax Fabric: Key Differences

Understanding how these two fabrics differ helps procurement professionals make informed decisions based on application-specific needs. Below is a detailed comparison across critical performance factors:

Appearance & Texture

- Wax Coated Fabric: Clean, matte finish with a crisp structure. The surface wax coating provides a dry hand feel that maintains a structured appearance over time, even after repeated handling.

- Oil Wax Fabric: Glossy, soft texture that gains visual character over time. Its surface may feel slightly tacky in warm temperatures, and it develops a marbled or patina effect that gives it a premium, vintage look.

Water Resistance

- Wax Coated Fabric: Offers surface-level water repellency. Water beads on the surface and rolls off easily, but extended exposure to moisture can eventually lead to saturation, making it suitable for intermittent or moderate weather conditions.

- Oil Wax Fabric: Provides deeper, fiber-level resistance to moisture. It holds up well in high-humidity environments and extended rain exposure, though care is needed to prevent oil migration or staining.

Durability & Maintenance

- Wax Coated Fabric: Exceptionally durable for rugged use. Its maintenance is simple: brush off dirt or wipe with a damp cloth. The coating can be easily refreshed with re-waxing, making it an ideal long-term fabric in high-wear environments.

- Oil Wax Fabric: Though durable, it demands more care. It can attract dust and oils, and improper storage can cause the finish to degrade unevenly. Reconditioning is not as straightforward and often requires professional treatment to restore appearance.

Use Cases in the Industry

Wax Coated Fabric: Built for Rugged Performance

Common Applications:

- Workwear & uniforms: Garments designed for labor-intensive fields like construction, electrical, and manufacturing.

- Outdoor equipment covers: Protect machinery and tools from the elements.

- Tool rolls & heavy-duty bags: Used in utility services, electrical repair kits, and field operations.

- Field tents & military tarps: Offer durability, weather resistance, and fast setup.

Industries Served:

- Construction: For protective covers, weather-resistant uniforms, and rugged utility storage.

- Mining: Used in site covers, tarpaulins, and gear bags where abrasion and UV resistance are key.

- Defense: Tents, canopies, and gear wraps where strength and function matter.

- Utilities: Maintenance staff often require weather-resistant workwear and transport covers.

- Agriculture: Storage covers, irrigation gear protectors, and field wear.

Oil Wax Fabric: A Blend of Function & Style

Common Applications:

- Fashion accessories and travel gear: Backpacks, satchels, and duffel bags with tactile appeal.

- Motorcycle jackets: Adds aesthetic flair while repelling moisture during rides.

- High-end aprons (e.g., for baristas, chefs): Provides both form and function with a premium touch.

- Premium packaging & branding items: Enhances the unboxing experience and adds value to custom goods.

Industries Served:

- Fashion & lifestyle: Footwear, outerwear, and accessories requiring a refined finish.

- Hospitality: Aprons, uniforms, or accent pieces that elevate brand image.

- Artisanal goods & retail: Boutique products where fabric feel and appearance drive consumer choice.

Insight: If you’re designing a luxury backpack line, oil wax fabric adds the tactile appeal your customers will remember.

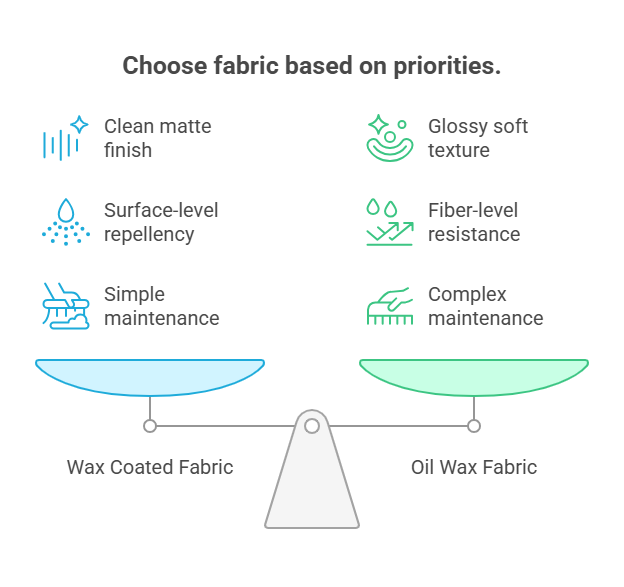

Which Fabric Should You Choose?

Choosing between these two fabrics is less about which is better and more about what your project demands:

Choose Wax Coated Fabric if:

- You need something highly durable and easy to maintain.

- Your end product is used in outdoor or industrial settings.

- A matte, structured appearance is preferred.

- Maintenance teams or end-users prefer fabrics that can be easily refreshed.

- Resistance to abrasions and heavy handling is a must.

Choose Oil Wax Fabric if:

- Aesthetics and feel are a priority.

- Your products are meant for consumer-facing or fashion markets.

- You’re okay with some extra care in storage and handling.

- Your brand values heritage, character, and texture in product design.

- You want a fabric that tells a visual story over time.

A procurement tip: Match your fabric not just to your use case but to your customer’s expectations. Rugged users value performance. Stylish buyers notice the details.

Conclusion

Though both wax-coated and oil wax fabrics begin from similar origins, their finishing methods, look, feel, and applications are vastly different.

For rugged, high-performance utility, wax-coated is a clear winner. For a tactile, luxurious finish, oil wax fabric adds the character your brand may need.

Understanding these differences helps ensure you make smart, cost-effective choices for your specific business and industry.

(Looking to source premium wax-coated or oil wax fabrics? We offer expert advice and tailored textile solutions based on your industry requirements. Speak to our specialists to find the right material for your next project.)

FAQs

1. Are wax-coated and oil-wax fabrics made from the same material?

Yes, both usually use cotton or canvas bases. The difference lies in the treatment process.

2. Which is more suitable for rough, outdoor conditions?

Wax-coated fabric is better suited for industrial and outdoor environments due to its rugged finish.

3. Does oil wax fabric leave a residue?

Sometimes, especially in warm environments. That’s why it’s used more often in fashion or controlled-use scenarios.

4. Can both be reconditioned?

Wax-coated fabrics can be easily re-waxed. Oil wax fabrics need professional refinishing.

5. Which fabric ages better visually?

Oil wax fabric develops a patina and unique texture over time that is perfect for vintage or upscale appeal.

Contact Information

- Mon - Sat: 10:00am-7:00pm

- 4/32-33 Triveni Nagar , Meerpur Cantt , Kanpur-208004

- +91 9839708040 | +91 9936159591

- gncfabrics@gmail.com

Quick Links

- About Us

- Products

- Blog

- Contact Us

© 2024 GNC EXPORTS, All rights reserved. Developed by DIGI PEXEL

- Privacy Policy

- Terms & Conditions

- Cookies Policy